Specialized Cleaning Kit: Essential Tools for Maintaining Your Vacuum

Discover which specialized tools belong in your vacuum maintenance kit to ensure optimal performance, extend your vacuum’s lifespan, and save money on repairs and replacements.

This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

Your vacuum cleaner works tirelessly to keep your home clean, but who’s taking care of the cleaner itself? Without proper maintenance, even the most expensive vacuum will lose suction, efficiency, and lifespan. Rather than relying on costly professional servicing or premature replacement, a specialized vacuum cleaning kit provides everything needed to maintain your vacuum’s performance. This comprehensive guide explores the essential tools that belong in every vacuum maintenance arsenal, helping you extend your appliance’s life and maintain its cleaning power.

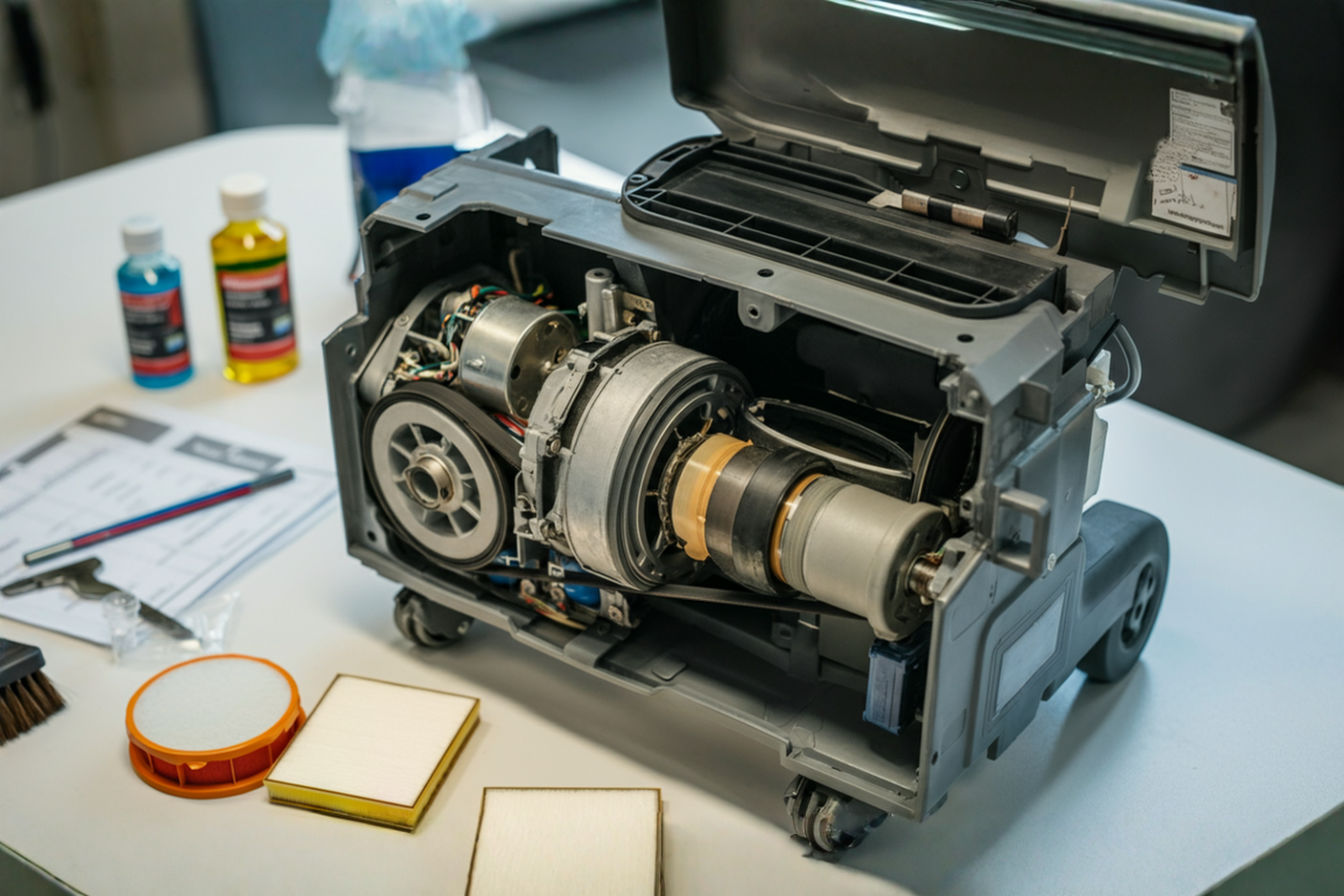

Most vacuum owners understand the basics of emptying the dust bin or changing a bag, but true maintenance goes much deeper. Hidden within your vacuum’s housing lies a complex system of filters, brushes, belts, and pathways that require regular attention. When these components become clogged with dust, tangled with hair, or worn from use, your vacuum’s performance suffers dramatically. The right maintenance tools allow you to address these issues efficiently, preventing the frustration of diminished suction and extending the operational life of your investment.

Developing a proper vacuum care kit isn’t just about prolonging your appliance’s life—it’s about ensuring consistent cleaning quality throughout that life. A well-maintained vacuum performs its job more effectively, removing more allergens, dust, and debris from your home environment. The tools we’ll explore provide access to otherwise hard-to-reach components, making maintenance faster and more thorough than improvised solutions. Whether you own an upright, canister, stick, or robotic model, these specialized tools will help keep your cleaning companion in peak condition.

Let’s explore the essential components of a comprehensive vacuum maintenance toolkit and how each tool addresses specific maintenance needs to keep your cleaner running like new.

Why Regular Vacuum Maintenance Matters

Extended Lifespan and Cost Savings

The average vacuum lifespan ranges from 5-8 years, but with proper maintenance, many models can last 12-15 years or longer. This extended life translates directly to significant cost savings. A quality vacuum cleaner can represent an investment of several hundred dollars, making premature replacement an unnecessary financial burden. Regular maintenance using appropriate tools prevents the cumulative damage that leads to early failure, maximizing your return on investment. The modest cost of a maintenance kit pays for itself many times over by delaying replacement purchases and avoiding professional repair services.

Beyond the direct savings on replacement costs, a well-maintained vacuum also operates more efficiently. This improved vacuum efficiency reduces electricity consumption during use, further contributing to long-term savings. The small, consistent effort of regular maintenance creates a compounding financial benefit that makes economic sense for any household budget.

Improved Cleaning Performance and Efficiency

A poorly maintained vacuum can lose up to 80% of its suction power without showing obvious external signs. This hidden performance decline means you’re working harder while achieving inferior results. Regular maintenance using specialized tools restores and preserves your vacuum’s cleaning performance, ensuring it continues to remove dirt effectively from carpets, upholstery, and hard floors.

Proper maintenance also reduces the time required for cleaning. When your vacuum operates at peak efficiency, fewer passes are needed to achieve clean surfaces. This time-saving benefit compounds with each cleaning session, adding up to hours saved annually. The improved air flow from clean filters and unobstructed pathways also reduces motor strain, lowering noise levels and providing a more pleasant cleaning experience overall.

Better Indoor Air Quality and Health Benefits

Vacuums don’t just clean floors—they play a crucial role in managing indoor air quality. A properly maintained vacuum with clean, functioning filters captures and contains allergens, dust mites, pet dander, and other microscopic particles. These maintenance benefits extend beyond visible cleanliness to create a healthier living environment, particularly important for households with allergy or asthma sufferers.

Conversely, a neglected vacuum with clogged filters can actually reduce air quality by recirculating fine dust particles back into your living space. Specialized filter cleaning tools ensure your vacuum’s filtration system operates as designed, capturing harmful particles rather than redistributing them. This hidden health benefit represents one of the most valuable aspects of comprehensive vacuum maintenance.

Environmental Impact and Sustainability

In our increasingly eco-conscious world, extending the life of household appliances represents a meaningful contribution to sustainability efforts. Every vacuum that doesn’t end up in a landfill due to proper maintenance reduces environmental impact. The manufacturing, packaging, and shipping of replacement units creates a substantial carbon footprint that can be minimized through proper care and maintenance.

Additionally, maintaining optimal vacuum efficiency reduces energy consumption during use. Over thousands of operating hours, this efficiency translates to tangible energy savings. By investing in quality maintenance tools and developing consistent care habits, you’re making an environmentally responsible choice that aligns with sustainable living principles.

Understanding Your Vacuum’s Maintenance Needs

Identifying Key Components Requiring Regular Maintenance

Every vacuum contains several critical vacuum components that require regular attention. Filters represent the most obvious maintenance point, with most vacuums containing multiple filtration stages. Pre-motor filters protect the engine from dust infiltration, while exhaust filters (sometimes HEPA-rated) ensure clean air output. Both require regular cleaning or replacement to maintain airflow and filtration quality.

The brush roll or beater bar represents another crucial maintenance point, particularly in homes with pets or long-haired residents. This rotating component captures debris but accumulates hair and thread that diminish its effectiveness. Similarly, belts that drive the brush roll stretch and wear with use, requiring periodic inspection and replacement. Hoses and attachments can develop clogs that restrict airflow, while gaskets and seals may deteriorate over time, allowing air leaks that compromise suction.

Different Maintenance Requirements by Vacuum Type

Maintenance requirements vary significantly across vacuum types. Upright vacuums typically need frequent brush roll cleaning and belt inspections. Their vertical design often incorporates multiple filtration stages requiring different cleaning approaches. Canister models, while sometimes simpler in brush design, often feature complex hose systems prone to internal clogs requiring specialized cleaning tools.

Stick and cordless vacuums present unique maintenance challenges with their compact designs and sometimes harder-to-access components. Their smaller dust containers necessitate more frequent emptying to maintain suction. Robotic vacuums require regular attention to brushes, wheels, and sensors to continue operating effectively. Central vacuum systems benefit from periodic power unit maintenance and occasional pipe system cleaning to prevent restriction buildup.

Warning Signs Your Vacuum Needs Attention

Several warning signs indicate your vacuum requires maintenance. Reduced suction represents the most common symptom, often accompanied by visible dust trails left behind during cleaning. Unusual noises—particularly high-pitched whining, grinding sounds, or labored motor operation—typically signal obstructions or mechanical issues requiring attention.

Overheating provides another clear indicator, with many modern vacuums featuring automatic shutoff protection when temperature thresholds are exceeded. Unpleasant odors during operation often indicate a full dust container, dirty filters, or organic material decomposing within the system. Visual inspections may reveal frayed cords, cracked hoses, or worn belts requiring immediate attention to prevent further damage or safety hazards.

Manufacturer Recommendations vs. Practical Reality

Manufacturer maintenance schedules provide useful guidelines but often represent ideal scenarios rather than practical reality. While some recommendations like filter replacement intervals are technically optimal, actual maintenance timing should account for your specific usage patterns and environment. Homes with pets, multiple occupants, or renovation activities require more frequent maintenance than the average recommendation.

Creating a realistic maintenance schedule requires balancing manufacturer guidelines with observation of your vacuum’s performance. Rather than adhering strictly to time-based recommendations, monitor for performance changes and adapt your maintenance routine accordingly. For many components, visual inspection provides the best indication of maintenance needs. This practical approach ensures your vacuum receives appropriate care without unnecessary labor or replacement part costs.

Essential Tools for Filter Maintenance

Filter Cleaning Brushes and Picks

Filter cleaning requires specialized tools designed to remove embedded particles without damaging delicate filter materials. Soft-bristled brushes with various widths allow gentle yet thorough cleaning of pleated filters, removing dust from deep crevices without compromising filter integrity. These purpose-designed brushes prevent the damage often caused by household cleaning tools, preserving filtration efficiency and extending filter life.

For stubborn debris or compressed dust, precision cleaning picks provide targeted access to specific areas without risk of puncturing or tearing filter material. Unlike improvised tools like toothpicks or wire, these rounded-tip implements safely dislodge particles from filter mesh. The combination of brushes and picks allows thorough cleaning of even the most complex vacuum filters, restoring airflow while maintaining filtration quality.

Compressed Air Systems for Deep Cleaning

Compressed air represents one of the most effective filter maintenance tools for deeply embedded particles. Purpose-designed compressed air canisters with precision nozzles allow controlled cleaning of pleated filters, removing dust from areas brushes cannot reach. Unlike household compressed air products used for electronics, vacuum-focused options provide appropriate pressure levels that clean effectively without damaging filter media.

For more frequent maintenance needs, reusable air pump systems offer an economical and environmentally friendly alternative to disposable canisters. These manual or electric pumps create targeted air pressure for filter cleaning while eliminating the ongoing expense of compressed air purchases. When using any air cleaning method, proper ventilation and particle containment prevent redistributing dust throughout your maintenance area.

Filter Washing and Drying Equipment

Many modern vacuums feature washable filters that require proper cleaning equipment and techniques. Specialized filter washing solutions provide effective cleaning without residues that could affect airflow or filtration performance. Unlike household detergents that may leave behind films or fragrance particles, these purpose-formulated cleaners rinse completely clean while removing embedded contaminants.

Proper drying represents an equally important aspect of filter maintenance. Mesh drying racks promote even airflow around washed filters, preventing mold growth and ensuring complete drying before reinstallation. Filter drying aids reduce downtime between cleaning and usage, particularly important for households with only one vacuum. Maintaining a rotation of clean filters eliminates the temptation to reinstall damp components that could damage your vacuum’s motor or electrical systems.

Replacement Filter Management Tools

Effective filter replacement requires proper management tools and systems. Filter tracking calendars or digital reminders help maintain appropriate replacement schedules based on manufacturer recommendations and actual usage patterns. Storage containers for replacement filters protect these sensitive components from damage, moisture, or contamination before installation.

Measurement tools ensure proper fitting when selecting aftermarket filter replacements, preventing air bypass issues that compromise filtration efficiency. Documentation systems track model numbers, sizes, and compatible alternatives, simplifying the reordering process and preventing costly purchasing errors. These management tools transform filter maintenance from a reactive emergency to a proactive, organized system that ensures continuous vacuum performance.

Brush Roll and Belt Maintenance Toolkit

Thread Cutters and Hair Removal Tools

The brush roll represents one of the most maintenance-intensive components in any vacuum, accumulating hair, thread, and fibers that wrap around its rotating core. Specialized thread cutters feature recessed blades that safely slice through entangled material without damaging brush bristles or bearings. Their curved designs access difficult angles, making quick work of even severely tangled brush rolls.

Complementing these cutters, precision hair removal tools extract cut debris without the frustration of manual unwinding. Their hooked designs catch and pull wrapped material away from the brush roll, completing the cleaning process. A quality maintenance kit includes multiple removal tool designs to address various brush roll configurations and entanglement types. These purpose-built tools dramatically reduce maintenance time while preventing the damage often caused by household scissors or knives.

Brush Roll Cleaning Combs and Brushes

Beyond entanglement issues, brush rolls accumulate embedded debris that reduces their effectiveness. Specialized brush roll cleaning combs with precisely spaced tines remove particles lodged between bristles without pulling or damaging the brush material. These combs restore proper bristle spacing and flexibility, critical for effective carpet cleaning.

For brush rolls with rubber fins or specialized picking surfaces, purpose-designed cleaning brushes remove embedded particles while preserving the textured surfaces. Unlike household cleaning tools, these brushes feature bristle arrangements specifically engineered for vacuum brush roll materials and configurations. Regular use maintains optimal brush contact with floor surfaces, ensuring maximum dirt extraction during routine cleaning.

Belt Replacement Toolset

Vacuum belts stretch and wear with normal use, requiring periodic inspection and replacement to maintain proper brush roll operation. A comprehensive belt replacement toolset includes specialized gripping tools that safely remove worn belts without damaging pulleys or adjacent components. These tools provide leverage in confined spaces where fingers cannot easily reach, simplifying a potentially frustrating maintenance task.

Belt tension gauges ensure proper installation of replacement belts, preventing issues from over-tightening or insufficient tension. Measurement tools confirm proper belt sizing when selecting replacements, particularly important with aftermarket options. Storage solutions for spare belts prevent deterioration from ozone exposure or improper stretching, ensuring they remain ready for use when needed.

Bearing and Axle Maintenance Implements

The brush roll’s rotation depends on properly functioning bearings and axles that require occasional maintenance. Precision lubricators apply appropriate amounts of bearing-specific lubricants without overflow that could attract additional debris. Their narrow applicator tips reach bearings without disassembling surrounding components, simplifying this important maintenance task.

Brushes designed specifically for bearing housings remove accumulated debris without forcing particles deeper into bearing assemblies. Inspection mirrors and lights allow visual assessment of bearing condition without complete disassembly, identifying wear before catastrophic failure occurs. These specialized implements extend brush roll bearing life, preventing the grinding and restriction that often leads to motor strain and belt failure.

Hose and Attachment Cleaning Equipment

Flexible Hose Cleaning Rods and Snakes

Vacuum hoses represent common clog points that require specialized tools for effective maintenance. Flexible hose cleaning rods combine appropriate rigidity for pushing through blockages with sufficient flexibility to navigate hose curves without causing damage. Unlike improvised solutions like broom handles or coat hangers, these purpose-designed tools won’t scratch or puncture hose interiors during use.

For more stubborn clogs, auger-style cleaning snakes feature rotating heads that break apart compacted debris while protecting hose integrity. Their flexible shafts conform to hose pathways while maintaining enough rigidity to transmit force to blockages. Extension capabilities accommodate various hose lengths, ensuring complete pathway cleaning from end to end. These specialized tools remove obstructions more effectively than improvised methods while reducing the risk of hose damage during cleaning.

Attachment Cleaning Brushes and Solutions

Vacuum attachments accumulate debris in crevices and internal mechanisms that affect performance. Specialized attachment brushes feature bristle arrangements designed to access these hard-to-reach areas, removing embedded particles without damaging plastic components. Their various shapes address the unique cleaning needs of crevice tools, upholstery attachments, and other specialized accessories.

Complementing these physical cleaning tools, safe cleaning solutions designed specifically for vacuum components remove stubborn residues without degrading plastics or rubber materials. Unlike household cleaners that may cause cracking or brittleness, these specialized formulations preserve attachment flexibility and durability. Microfiber cloths paired with these solutions complete the attachment cleaning process, restoring original performance and extending useful life.

Clog Removal Tools and Techniques

Beyond hoses, vacuum pathways contain multiple potential clog points requiring specialized unclogging tools. Thin, flexible probes access narrow channels in floor heads and attachment connectors, dislodging obstructions without disassembly. Their non-marring materials prevent interior surface damage that could create future clog points.

For intake ports and transition points, angled cleaning tools reach around corners and into recessed areas where debris accumulates. Compressed air tools with focused nozzles provide controlled force for dislodging compacted materials from pathways without disassembly. These specialized implements transform time-consuming clog removal tasks into quick maintenance procedures, restoring full airflow with minimal effort.

Connection Point Maintenance Equipment

Connection points between hoses, wands, and attachments often develop air leaks that compromise suction power. Specialized gasket picks safely remove and clean sealing surfaces without damaging the surrounding plastic or metal components. Their precision tips access narrow sealing channels that harbor debris, restoring proper connection integrity.

Gasket conditioning products preserve rubber and silicone seals, preventing the drying and cracking that leads to air leaks. Application tools ensure even coverage without excess product that could attract additional debris. Measurement tools help identify correct replacement gasket sizes when conditioning no longer restores proper sealing function. These specialized maintenance items address often-overlooked connection points that significantly impact overall vacuum performance.

Motor and Electrical Component Care Tools

Ventilation Cleaning Equipment

Vacuum motors rely on continuous airflow for cooling during operation. Over time, ventilation pathways accumulate dust that restricts this critical airflow, potentially leading to overheating and premature motor failure. Specialized ventilation cleaning brushes feature bristle arrangements designed to access these cooling channels without entering the motor housing itself, removing accumulated debris safely.

Precision air delivery systems provide controlled pressure for clearing cooling fins and motor housing vents without forcing dust deeper into motor components. Their focused nozzles direct air precisely where needed, unlike general-purpose compressed air that may cause collateral contamination. Regular use of these specialized tools prevents the heat buildup that represents one of the most common causes of vacuum motor failure.

Safe Electrical Connection Maintenance

Electrical components require periodic inspection and cleaning to maintain proper function. Contact cleaning tools with non-conductive handles safely remove oxidation and debris from electrical connections without shock hazard. Their precision tips access recessed electrical contacts without damaging surrounding components, restoring proper conductivity.

Specialized electrical contact cleaners remove residue without leaving films that could attract additional debris. Unlike household cleaning products, these formulations evaporate completely without compromising electrical insulation or component integrity. Application tools ensure precise delivery to specific connection points without overspray that could affect nearby electronics. These specialized items address often-overlooked electrical maintenance needs that impact motor performance and control system function.

Motor Housing Cleaning Tools

External motor housing surfaces accumulate dust that can eventually migrate into internal components. Extended-reach cleaning brushes access these surfaces without disassembling protective covers, removing accumulated debris before it can cause damage. Their specially designed bristles prevent static electricity generation that could attract additional particles during cleaning.

For more thorough maintenance, gasket cleaning tools prepare housing seams for proper reassembly after authorized internal access. Their precision edges remove old gasket material without scratching sealing surfaces, ensuring proper closure and dust sealing upon reassembly. These specialized tools allow appropriate external motor maintenance while respecting manufacturer boundaries regarding internal component access.

Heat Management and Prevention

Overheating prevention represents a critical aspect of vacuum motor maintenance. Thermal imaging tools identify developing hot spots before they cause performance issues, allowing preemptive maintenance. While professional-grade thermal cameras exceed most home maintenance budgets, affordable infrared thermometers provide useful temperature readings to identify potential problems.

Airflow measurement tools assess cooling system performance, identifying restriction points before they cause overheating. Their sensitive sensors detect subtle airflow reductions that precede noticeable performance issues. Supplemental cooling accessories for heavy-use environments provide additional airflow during extended operation, preventing the heat accumulation that leads to component failure. These specialized thermal management tools address the primary cause of premature motor failure, significantly extending vacuum lifespan.

Specialized Tools for Different Vacuum Types

Upright Vacuum-Specific Maintenance Tools

Upright vacuum designs present unique maintenance challenges requiring specialized tools. Belt access tools designed specifically for popular upright models simplify the otherwise frustrating process of belt replacement. Their leveraged designs provide the necessary force to remove and install belts without damaging surrounding components or risking personal injury during the process.

Brush roll removal tools designed for specific upright configurations allow quick access without complete disassembly. These specialized implements often combine multiple functions, releasing retention clips while simultaneously extracting the brush assembly. Height adjustment mechanism cleaning tools access these often-neglected components, removing debris that affects floor adaptation and cleaning effectiveness. A comprehensive maintenance kit includes model-specific tools that address the particular requirements of your upright vacuum design.

Canister Vacuum Specialized Equipment

Canister vacuum models feature unique components requiring specialized maintenance tools. Hose-to-body connection cleaning implements access the critical juncture where airflow transitions from hose to dust collection chamber, removing debris that restricts suction at this crucial point. Their angled designs reach around the typical bends found in these connection points, maintaining proper airflow.

Wheel axle cleaning and lubrication tools address the mobility components that often accumulate string and hair, affecting ease of movement. Power head connection maintenance implements clean the electrical contacts that transfer power from the canister to motorized attachments, ensuring reliable operation. Storage accessories designed specifically for canister hoses prevent the kinking and crushing that leads to premature hose failure, extending this expensive component’s useful life.

Stick and Cordless Vacuum Maintenance

The compact design of stick and cordless vacuums creates unique maintenance challenges. Battery contact cleaning tools safely remove oxidation from power transfer points without damaging sensitive electronic components. Their precision tips access recessed battery connections while protecting surrounding circuitry from cleaning solution exposure.

Compact filter cleaning tools address the specialized filtration systems found in these space-efficient designs. Mini motorized brush cleaning implements accommodate the smaller dimensions of stick vacuum power heads without damage. Charging port maintenance tools ensure reliable power transfer for battery recharging, preventing the connection issues that lead to charging failures. These specialized tools address the particular requirements of increasingly popular stick and cordless designs.

Robotic Vacuum Cleaning and Maintenance Kit

Robotic vacuum maintenance presents entirely different challenges from traditional vacuum designs. Sensor cleaning tools gently remove dust from optical and infrared sensors without scratching sensitive surfaces, maintaining proper navigation and obstacle detection. Wheel module cleaning implements remove hair and debris from drive mechanisms without damaging the complex components housed within.

Brush and roller cleaning combs designed specifically for the compact dimensions of robotic vacuums address their unique brush configurations. Edge cleaning tool maintenance implements ensure proper function of the specialized brushes that access wall edges and corners. These purpose-designed tools maintain the sophisticated technology that allows robotic vacuums to function autonomously, preserving both cleaning and navigation capabilities.

Central Vacuum System Tools

Central vacuum systems require maintenance tools addressing both the central power unit and the extensive pipe network. Power unit filter cleaning implements accommodate the larger dimensions typical of these systems, maintaining proper airflow through the main collection chamber. Motor cooling system maintenance tools ensure proper heat dissipation during the extended duty cycles these systems often experience.

Pipe system cleaning equipment addresses the extensive hidden pathway network that distinguishes central systems from portable vacuums. Specialized augers designed for the wider diameter pipes remove blockages without damage, while pipe system testing tools identify restriction or leak points within walls. Inlet valve maintenance implements ensure proper sealing and electrical contact at each connection point. These specialized tools maintain the substantial investment represented by whole-house vacuum systems.

DIY vs. Commercial Vacuum Cleaning Kits

Building Your Own Custom Maintenance Kit

Creating a personalized DIY cleaning kit offers significant advantages for vacuum maintenance. This approach allows precise selection of tools addressing your specific vacuum’s requirements rather than accepting the generic implements found in pre-assembled kits. Begin by identifying your vacuum’s particular maintenance points and selecting specialized tools for each area, prioritizing quality over quantity for frequently used implements.

Cost efficiency represents another significant advantage of the custom approach. By purchasing only necessary tools rather than accepting bundled items you’ll rarely use, your maintenance investment focuses on genuine needs. Consider beginning with essential tools addressing common maintenance tasks, then expanding your collection as specific needs arise. This gradual approach spreads the investment over time while ensuring you have appropriate tools when needed.

Pre-assembled Commercial Kits: Pros and Cons

Commercial maintenance kits offer convenience and curation advantages worth considering. Quality pre-assembled kits undergo professional selection, combining tools with proven compatibility and effectiveness. This expert curation often introduces maintenance implements you might not have considered, potentially improving your maintenance routine. The immediate availability of a complete tool collection ensures you’re prepared for various maintenance scenarios without additional purchases.

However, commercial kits present potential disadvantages. Many include generalized tools rather than model-specific implements, potentially lacking optimal designs for your particular vacuum. Price premiums for packaged solutions often exceed the cost of individually purchased equivalents, particularly when kits include items unnecessary for your specific maintenance needs. Research manufacturer-specific kits before purchasing generic options, as these often provide better component alignment with your vacuum’s particular requirements.

Cost Comparison and Value Analysis

When evaluating cost comparison between DIY and commercial options, consider multiple factors beyond initial purchase price. Quality differences often exist between individually selected professional-grade tools and the sometimes lower-quality implements included in pre-assembled kits. The inclusion of unnecessary tools in commercial kits effectively increases the per-tool cost of items you’ll actually use, potentially diminishing overall value.

Conversely, the convenience value of immediate toolkit availability merits consideration. The time required to research and source individual tools represents a hidden cost in the DIY approach. For those new to vacuum maintenance, the guidance implicit in a well-organized commercial kit may justify premium pricing through reduced learning curve and mistake avoidance. Evaluate your personal situation, maintenance knowledge, and time value when making this cost-benefit determination.

Essential vs. Nice-to-Have Tools

Distinguishing between essential tools and convenience items helps optimize your maintenance investment. Core maintenance requires relatively few specialized implements—quality brush cleaning tools, appropriate filter maintenance items, and basic disassembly implements address most routine tasks. Prioritize these foundational items when building your maintenance toolkit, ensuring you have proper equipment for the most frequent maintenance needs.

As your maintenance confidence grows, consider adding specialized implements that improve efficiency rather than enabling new capabilities. Organized storage solutions, specialized lubricants, and precision cleaning tools enhance the maintenance experience without being strictly necessary. This tiered approach ensures your initial investment addresses critical needs while allowing future expansion as interest and circumstances warrant.

Maintenance Schedule and Best Practices

Creating an Effective Maintenance Calendar

A structured vacuum maintenance schedule transforms sporadic emergency interventions into systematic care that prevents problems before they develop. Begin by documenting manufacturer recommendations for each maintenance point, then adapt these guidelines to your specific usage patterns and environmental conditions. Homes with pets, multiple users, or renovation activities typically require more frequent maintenance than manufacturer baselines suggest.

Digital calendar reminders effectively prompt routine maintenance tasks without relying on memory. Create recurring alerts for different maintenance frequencies—weekly quick checks, monthly deep cleaning, and quarterly comprehensive inspection. These structured reminders ensure consistent attention without creating overwhelming maintenance burdens. Consider aligning vacuum maintenance with other household routines to establish sustainable habits that improve compliance.

Quick Maintenance vs. Deep Cleaning Sessions

Effective maintenance strategies distinguish between frequent quick procedures and more thorough periodic interventions. Quick maintenance—emptying dust containers, checking filters, and removing visible brush roll tangles—requires just minutes but prevents accumulating damage. Incorporate these brief procedures into your regular cleaning routine, addressing minor issues before they affect performance.

Deep cleaning frequency follows a different schedule, typically monthly or quarterly depending on usage. These more comprehensive sessions include filter washing, brush roll removal and cleaning, hose inspection, and motor ventilation assessment. Allocate appropriate time for these thorough procedures rather than attempting to incorporate them into regular cleaning sessions. This tiered approach balances maintenance effectiveness with practical time constraints.

Proper Tool Usage Techniques

Even the finest maintenance tools provide limited benefit without proper usage techniques. Before attempting maintenance procedures, review manufacturer documentation for disassembly guidance and component access. Many vacuums feature specific release mechanisms requiring particular approaches to prevent damage during routine maintenance.

Apply appropriate force levels when using maintenance tools—sufficient pressure to accomplish the task without risking component damage. Many vacuum parts use plastic retention clips that can break under excessive force. Similarly, use cleaning solutions sparingly on electrical components, applying them to cloths rather than spraying directly onto vacuum parts. These mindful techniques preserve both your vacuum and maintenance tools for extended service.

Storage Solutions for Your Maintenance Kit

Proper tool storage preserves your maintenance investment while improving usage convenience. Purpose-designed storage cases protect specialized tools from damage while keeping components organized for easy access. Consider transparent cases that allow visual identification of needed tools without unpacking the entire collection.

Magnetic tool organization systems prevent small components from becoming lost during maintenance procedures. Their secure holding power keeps implements readily available during disassembly while preventing them from rolling into inaccessible areas. Wall-mounted storage near your vacuum’s regular location ensures maintenance tools remain readily accessible when needed, encouraging regular preventive maintenance rather than deadline-driven emergency intervention.

Troubleshooting Common Vacuum Issues

Diagnosing Suction Loss Problems

Reduced suction represents the most common vacuum troubleshooting scenario, typically stemming from specific identifiable causes. Begin diagnosis with the simplest possibilities—check the dust container or bag for fullness, as even partially filled containers can restrict airflow in some designs. Inspect hose connections for proper seating, as even slight misalignment creates air leaks that dramatically reduce suction.

If basic checks reveal no issues, examine filters for clogging—both pre-motor and exhaust filters require regular cleaning to maintain airflow. Remove the hose and check for blockages throughout its length, as even small obstructions significantly impact performance. Inspect the brush roll for hair entanglement that prevents proper rotation, another common suction loss cause. This systematic approach identifies most suction issues without requiring professional intervention.

Addressing Unusual Noises and Vibrations

Unusual operating sounds often provide valuable diagnostic information regarding developing common problems. High-pitched whining typically indicates restricted airflow through filters or pathways, while grinding noises usually signal brush roll bearing issues or foreign objects caught in rotating components. Rattling sounds most often stem from loose components or objects caught in the dust container.

Begin addressing noise issues by emptying the dust container and removing the brush roll for inspection. Clear any foreign objects and remove hair entanglement from rotating components. Check filter seating and condition, ensuring proper positioning without gaps that create whistling sounds. Inspect hose connections for proper seating and gasket condition. This methodical approach resolves most noise issues while identifying those requiring professional attention.

Resolving Overheating Issues

Vacuum overheating presents both performance and safety concerns requiring prompt attention. Modern vacuums incorporate thermal cutoff protection that stops operation when temperature thresholds are exceeded. If your vacuum repeatedly shuts down during use, immediate maintenance intervention prevents potential damage.

Begin by checking airflow pathways—clogged filters, blocked hoses, and full dust containers all restrict the airflow that cools the motor during operation. Clean or replace filters, clear any hose blockages, and empty the dust container completely. Check motor housing ventilation openings for dust accumulation that restricts cooling airflow. Allow the vacuum to cool completely before testing, then operate in short intervals to confirm proper cooling function has been restored.

When to Seek Professional Repair

While DIY vacuum maintenance resolves most issues, certain scenarios warrant professional repair consultation. Internal electrical issues—particularly those involving power cords, switches, or motor wiring—present both repair complexity and safety hazards best addressed by qualified technicians. Similarly, motor replacement exceeds most home maintenance capabilities, requiring professional intervention.

Unusual burning odors during operation signal potential motor or electrical issues requiring immediate professional attention. Persistent overheating despite thorough maintenance likely indicates internal problems beyond DIY capabilities. Water ingestion into motor components almost always necessitates professional servicing to prevent electrical hazards. Recognizing these limitation boundaries preserves safety while preventing costly damage from well-intentioned but inappropriate repair attempts.

Conclusion: Maintaining Your Vacuum Maintenance Kit

A well-equipped vacuum cleaning kit transforms routine maintenance from a dreaded chore to a straightforward process that extends your appliance’s useful life. The specialized tools we’ve explored provide access to otherwise hard-to-reach components, making maintenance faster and more effective than improvised solutions. By addressing each vacuum system—filtration, brush mechanics, airflow pathways, and motor cooling—these essential tools ensure comprehensive care that preserves both performance and longevity.

Creating your maintenance toolkit represents an investment in your vacuum’s future, preventing the frustration of poor performance and premature replacement. Whether you choose a commercial kit or assemble custom tools addressing your specific vacuum’s needs, the return on investment comes through years of additional service and consistent cleaning effectiveness. The modest cost of quality maintenance implements pays dividends through extended vacuum life and improved cleaning performance.

Establish a regular maintenance schedule that balances thoroughness with practicality, incorporating quick checks into your routine while scheduling more comprehensive sessions at appropriate intervals. Store your maintenance toolkit in an accessible location that encourages preventive care rather than deadline-driven emergency intervention. This systematic approach transforms vacuum maintenance from reactive emergency repair to proactive care that prevents problems before they develop.

Your vacuum works tirelessly to keep your home clean—return the favor by providing the specialized care it needs to perform efficiently for years to come. With the right tools and maintenance habits, you’ll enjoy consistent cleaning performance while maximizing your vacuum investment’s return through extended useful life and reduced operating costs.