Electronics and Computer Cleaning: Gentle Vacuum Methods for Sensitive Equipment

Learn the science of safely removing dust from electronics using vacuum methods. Our detailed guide covers everything from specialized tools to step-by-step cleaning techniques for all your valuable equipment.

This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

Modern electronics collect dust and debris at an alarming rate. That innocent-looking layer of dust on your computer isn’t just unsightly—it’s actively degrading performance, shortening component lifespan, and potentially setting the stage for catastrophic failures. While regular cleaning is essential, approaching sensitive electronics with the wrong tools can cause more harm than the dust itself.

Vacuum cleaning offers an effective solution for removing dust from electronics, but it’s not as simple as grabbing your household vacuum cleaner. The delicate components in computers and electronics require specialized approaches to prevent damage from static electricity, excessive suction, and improper handling.

This comprehensive guide explores safe vacuum cleaning methods for all your sensitive electronic equipment. We’ll cover everything from the science behind electronics cleaning to step-by-step procedures for different devices. Whether you’re a home user wanting to maintain your personal computer or an IT professional responsible for an entire data center, you’ll find practical, actionable advice for keeping your equipment clean, cool, and functioning optimally.

Understanding the Risks of Dust and Debris

Before diving into cleaning methods, it’s important to understand exactly why dust poses such a significant threat to electronic equipment.

The Silent Performance Killer

Dust isn’t just a cosmetic issue—it’s a functional impediment to your electronics’ operation. When dust accumulates on components, it creates a thermal insulating layer that prevents proper heat dissipation. Electronic components generate heat during operation, and manufacturers design cooling systems based on clean operating conditions. Even a thin layer of dust can raise operating temperatures by 10-30°F.

For processors and graphics cards, this temperature increase can trigger thermal throttling, where the component deliberately reduces performance to prevent overheating. The result? Your once-speedy computer now runs slower, struggles with demanding tasks, and may crash during intensive operations.

Critical Airflow Obstruction

Modern computers and electronics rely on carefully engineered airflow patterns to maintain optimal operating temperatures. Cooling fans create pressure differentials that direct air across hot components before exhausting it from the case.

Dust buildup on intake filters, fan blades, heatsinks, and vents disrupts these airflow patterns, reducing cooling efficiency dramatically. A CPU heatsink clogged with dust might operate at 50-60% of its designed cooling capacity, while dust-coated fans work harder while moving less air.

Fan motors straining against dust accumulation draw more power and wear out prematurely. In severe cases, this can lead to fan failure, causing rapid overheating and potential system damage.

Electrical Hazards and Component Degradation

Dust isn’t just dry particles—it often contains conductive elements like metal fragments, carbon particles, and moisture. This conductive dust creates multiple risks:

- Short circuits: Conductive dust bridges between electrical contacts can create unintended paths for electricity, potentially damaging components instantly.

- Signal interference: On circuit boards and in sensitive communication equipment, dust can degrade signal quality, leading to data errors and connectivity issues.

- Corrosion acceleration: Dust often absorbs moisture from the air and holds it against metal surfaces, speeding up corrosion processes, particularly on connection points and traces.

In data centers and network equipment, these issues scale dramatically, with dust potentially affecting thousands of connections simultaneously.

The Compound Effect Over Time

Perhaps most concerning is that dust damage is cumulative and progressive. Dust attracts more dust, creates static charge buildups, and becomes increasingly difficult to remove as it combines with oils and moisture. Components operating at higher temperatures due to dust insulation age faster, with semiconductor lifespan decreasing exponentially as temperatures rise.

Research indicates that proper dust management can extend equipment lifespan by 30-50% and maintain performance closer to original specifications throughout that extended life.

Why Vacuum Cleaning Requires Special Consideration

While vacuuming might seem like an obvious solution for dust removal, applying the wrong vacuum cleaning approach to electronics can result in catastrophic damage. Understanding these risks is essential before attempting any cleaning procedure.

The Static Electricity Danger

Standard household vacuum cleaners generate significant static electricity during operation. This occurs through the friction of air and dust particles moving through plastic hoses and components—a process called triboelectric charging.

These static charges can reach several thousand volts, far exceeding the tolerance of sensitive electronic components like:

- CPUs and GPUs (damaged by as little as 100-200 volts)

- RAM modules (vulnerable to 200-500 volts)

- Motherboard components (many damaged at 500-1000 volts)

- Hard drive controller circuits (can fail at 300-700 volts)

The most insidious aspect of static damage is that it may not cause immediate, obvious failure. Instead, it can weaken components, causing intermittent issues or premature failure weeks or months later. This type of damage—known as latent ESD failure—accounts for a significant percentage of “mysterious” electronic failures.

Suction Power: Finding the Right Balance

Vacuum cleaners designed for household cleaning generate substantial suction—typically 50-100 CFM (cubic feet per minute) of airflow. This powerful suction can:

- Dislodge small surface-mounted components from circuit boards

- Pull loose wires and connections

- Damage delicate fan blades by spinning them beyond their rated speeds

- Stress or break fragile internal connections

At the same time, insufficient suction won’t effectively remove dust, particularly from dense heatsink fins and tight spaces. Finding the right balance is critical for effective yet safe cleaning.

Comparison with Alternative Cleaning Methods

To understand the advantages and limitations of vacuum cleaning, let’s compare it with other common approaches:

| Cleaning Method | Advantages | Disadvantages |

|---|---|---|

| Vacuum Cleaning | Removes dust completely from system; Prevents dust redistribution; Can access many areas without disassembly | Static electricity risk; Potential mechanical damage; Initial equipment cost |

| Compressed Air | Readily available; Simple to use; Good for keyboard cleaning | Merely relocates dust within system; Can damage fans if spun too fast; Contains moisture when used extensively; Environmental impact of disposable cans |

| Microfiber Cloths | Safe for external surfaces; No static risk; Inexpensive | Limited access to internal components; Not effective for heavy dust buildup |

| Isopropyl Alcohol | Dissolves stubborn residues; Evaporates completely; Disinfects | Not suitable for dust removal; Requires significant disassembly; Risk of liquid damage |

Vacuum cleaning, when done correctly with appropriate equipment, offers the most complete dust removal while minimizing the redistribution of particles within the system.

ESD Fundamentals for Electronics Cleaning

To understand safe vacuum cleaning, you need a basic grasp of Electrostatic Discharge (ESD) principles:

ESD occurs when two objects with different electrical charges come into contact, causing a rapid transfer of electrons. The human body can easily generate 15,000+ volts just by walking across carpet, while most electronic components can be damaged by as little as 100 volts.

ESD protection works by either preventing charge buildup in the first place or providing safe paths for charges to equalize gradually rather than in a damaging spark. This is achieved through conductive or static-dissipative materials that safely channel static charges to ground.

Proper ESD-safe equipment includes:

- Conductive pathways to ground electrical charges

- Static-dissipative materials that don’t generate charges through friction

- Humidity control (40-60% relative humidity reduces static buildup)

When selecting vacuum equipment for electronics, these ESD considerations should be primary factors in your decision-making process.

Risk Assessment by Device Type

Different electronic devices carry different levels of vacuum cleaning risk:

Highest Risk Devices:

- Bare circuit boards

- Open desktop computers

- Disassembled laptops

- Server blades removed from chassis

- Network switches with exposed PCBs

Moderate Risk Devices:

- Assembled desktop computers (internal cleaning)

- Laptop cooling systems

- Keyboards and peripherals

- External hard drives

- Audio equipment and amplifiers

Lower Risk Devices:

- External computer cases (without opening)

- Monitor and TV exteriors

- Closed equipment with filtered vents

- Power supplies (external only)

- Cable management areas

This risk assessment should guide your approach to cleaning each device type, with higher risk devices requiring more precautions and specialized equipment.

Specialized Tools for Safe Vacuum Cleaning

The right tools make all the difference between dangerous improvisation and safe, effective electronics cleaning. This section explores the specialized equipment designed specifically for electronics vacuum cleaning.

ESD-Safe Vacuum Cleaners: What Makes Them Different

ESD-safe vacuums differ fundamentally from regular household vacuums in several critical ways:

Conductive Construction: These specialized vacuums use conductive materials throughout their construction—from the nozzle tip to the collection chamber. This creates a continuous path for static charges to flow to ground rather than building up.

Grounding Systems: Professional ESD vacuums feature dedicated grounding wires that connect to electrical ground, ensuring any static charge is safely dissipated. The most effective units include verification systems that confirm proper grounding before operation.

Controlled Suction: Electronics vacuums typically offer 50-70% less suction power than standard vacuums, providing enough force to remove dust without endangering components. Many feature adjustable suction settings for different cleaning scenarios.

HEPA Filtration: High-efficiency particulate air (HEPA) filters capture 99.97% of particles 0.3 microns or larger, preventing the finest dust from being recirculated. This is particularly important in clean environments like server rooms.

Carbon Brush Motors: Unlike standard vacuum motors that generate significant static, ESD-safe vacuums use specialized carbon brush motors designed to minimize static generation during operation.

Popular models in this category include the DataVac ESD-Safe, MetroVac ESD-Safe, and 3M Electronics Vacuum systems, with prices ranging from $200 for basic models to $800+ for professional-grade systems.

Low-Power Vacuum Options for Home Users

Not everyone needs or can afford professional ESD-safe equipment. For home users and small offices, several middle-ground options exist:

USB-Powered Mini Vacuums: Drawing power from a computer’s USB port naturally limits their suction power to safe levels. Models like the OPOLAR Compressed Air Electric Duster ($30-50) provide enough suction for keyboard cleaning and light dust removal while generating minimal static.

Battery-Operated Electronics Vacuums: These units typically operate at 3-6 volts (compared to 120V for household vacuums), significantly reducing both suction strength and static generation. The XPOWER A-2 Airrow Pro ($75-100) represents this category well.

Variable-Speed Standard Vacuums: Some standard vacuums offer very low power settings that, when combined with anti-static accessories, can be used with caution for external computer cleaning. The Shark Navigator with adjustable suction control can work when used at minimum power with proper attachments.

While these options don’t provide the same level of protection as true ESD-safe vacuums, they present a reasonable compromise for occasional home use when proper techniques are followed.

Essential Attachments and Accessories

The right attachments transform a vacuum from a blunt instrument to a precision tool:

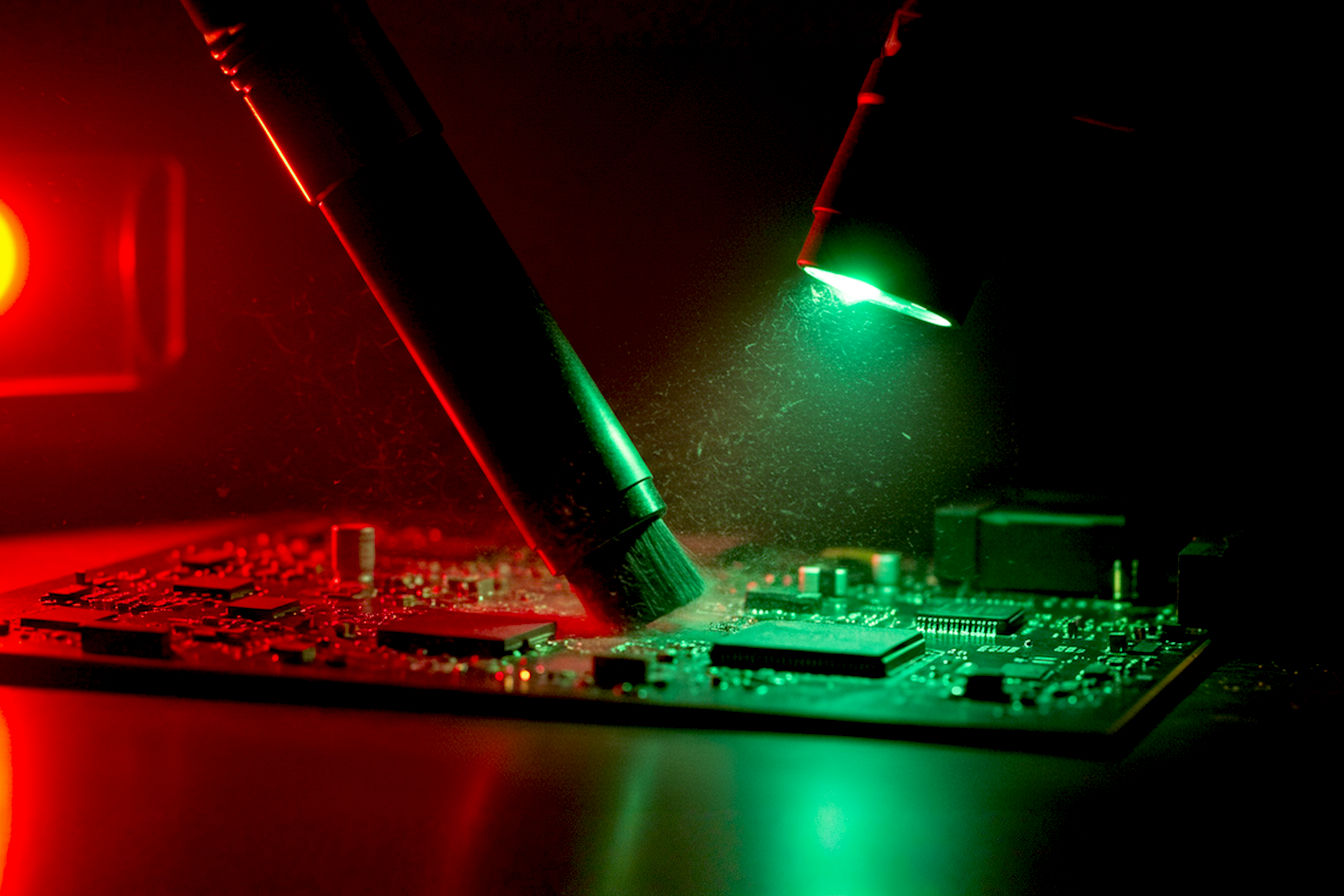

Anti-Static Brush Attachments: These special brushes have conductive bristles that help neutralize static charges while loosening dust. The bristles are soft enough to prevent scratching delicate surfaces but firm enough to dislodge dust.

Precision Nozzles: Narrow-diameter nozzles allow access to tight spaces between components. The best designs feature non-marring rubber or soft plastic tips to prevent scratching.

Extension Wands: Rigid plastic or metal extension wands help reach deep into computer cases without disassembly. Look for non-conductive varieties or those with proper grounding.

Crevice Tools: These flat, wide attachments are ideal for cleaning keyboard surfaces and the narrow vents found on many electronics.

Microfilters and Dust Bags: These consumables capture dust particles as small as 1 micron, preventing them from being exhausted back into the environment.

A complete kit of quality attachments typically costs $30-60 but dramatically improves cleaning effectiveness and safety.

Anti-Static Equipment and Materials

Beyond the vacuum itself, several complementary items enhance safety:

ESD Wrist Straps: These simple devices connect your body to electrical ground, preventing static buildup. Basic models start around $10, while professional versions with resistance verification cost $30-50.

Anti-Static Mats: Placing electronics on anti-static mats during cleaning provides additional protection. These mats ($20-100 depending on size) conduct static charges safely away from sensitive components.

Anti-Static Sprays: These solutions temporarily increase the surface conductivity of non-conductive materials, reducing static generation. MetroVac Anti-Static Spray ($15-20 per bottle) can be applied to work surfaces and exterior plastic components.

Humidity Control: Maintaining room humidity between 40-60% significantly reduces static generation. Simple room humidifiers ($30-100) can make a substantial difference in dry environments.

These accessories significantly enhance safety when used properly alongside appropriate vacuum equipment.

DIY vs. Commercial Solutions: Cost-Benefit Analysis

When deciding between DIY approaches and commercial solutions, consider:

DIY Approach:

- Cost: $75-150 for basic equipment

- Effectiveness: 60-80% dust removal

- Safety: Moderate risk with proper precautions

- Time Investment: Higher, requiring more careful work

- Best For: Occasional cleaning of personal equipment

Commercial Solutions:

- Cost: $300-1000 for professional equipment

- Effectiveness: 90%+ dust removal

- Safety: High with proper training

- Time Investment: Lower, more efficient process

- Best For: Regular cleaning of multiple systems, business environments

For most home users, a middle-ground approach makes sense: investing in a quality USB or battery-powered vacuum with proper attachments provides reasonable safety and effectiveness for personal equipment. IT departments and professionals should consider proper ESD-safe systems as essential equipment.

Step-by-Step Guide to Vacuum Cleaning Computers

With an understanding of the tools and risks, let’s walk through the comprehensive process of safely vacuum cleaning a desktop computer.

Preparation and Safety Precautions

Proper preparation minimizes risks and ensures effective cleaning:

- Power down completely: Shut down the computer and disconnect the power cord from the wall. For desktop PCs, flip the power supply switch to the off position if available.

- Wait 5-10 minutes: This allows time for capacitors to discharge and components to cool down, reducing both electrical and burn risks.

- Work in an appropriate environment:

- Room humidity between 40-60% (use a humidifier if necessary)

- Clean, well-lit workspace with sufficient room

- Non-carpeted floor or anti-static mat underneath

- Away from other electronics that could be affected by dust

- Wear appropriate safety gear:

- ESD wrist strap connected to a proper ground point

- Latex or nitrile gloves if handling components directly

- Eye protection if using compressed air alongside vacuum methods

- Prepare your vacuum equipment:

- Verify the vacuum is ESD-safe or appropriate for electronics

- Check that all attachments are clean and in good condition

- Test suction level on a non-sensitive surface

- Ensure any grounding wires are properly connected

- Document before cleaning: Taking photos before disassembly helps with reassembly and provides a baseline to assess cleaning effectiveness.

- Gather secondary tools: Have microfiber cloths, cotton swabs, and isopropyl alcohol (91%+) on hand for supplementary cleaning.

This preparation process typically takes 15-20 minutes but dramatically reduces the risk of damage.

External Case and Vent Cleaning

Start with the exterior to prevent pushing external dust inside the system:

- Begin with the power supply vents: Using a low-suction setting and brush attachment, gently vacuum the power supply intake and exhaust grilles. Circular motions are most effective at loosening dust without pushing it deeper into the vents.

- Clean case intake filters: Many modern cases have removable dust filters. If present:

- Carefully remove according to manufacturer instructions

- Vacuum with a brush attachment on both sides

- For stubborn dust, rinse with warm water and dry completely before reinstallation

- Address external ports and recesses: Use precision nozzle attachments to clean:

- USB, HDMI, and other connection ports

- Memory card readers

- Audio jacks

- Case seams and edges

- Clean ventilation grilles: Most cases have additional ventilation holes or mesh panels:

- Vacuum using broad sweeping motions

- Pay special attention to areas near fans

- Use brush attachments to loosen stubborn dust

- Wipe down exterior surfaces: After vacuuming, use a slightly dampened microfiber cloth to remove residual dust from flat surfaces.

This external cleaning process typically takes 10-15 minutes and should be performed monthly even if internal cleaning is done less frequently.

Internal Component Cleaning Considerations

Internal cleaning requires additional care and attention to detail:

- Access the interior: Remove the side panel(s) according to manufacturer instructions, typically by removing thumbscrews or sliding release mechanisms.

- Ground yourself: Connect your ESD wrist strap to an unpainted metal portion of the computer case.

- Initial assessment: Without touching components, visually identify the dustiest areas requiring attention. Common problem spots include:

- CPU heatsink and fan

- Graphics card heatsink and fan

- Case fans (intake and exhaust)

- RAM slots and modules

- Drive bays

- Power supply (external cleaning only)

- Remove loose dust first: Hold the vacuum nozzle 1-2 inches away from components and use gentle sweeping motions to capture loose dust without direct contact.

- Work top to bottom: Dust falls with gravity, so start cleaning from the top of the case working downward.

- Maintain safe distances: Keep vacuum nozzles at least 1/2 inch away from circuit boards and sensitive components. Use brush attachments when cleaning closer to prevent accidental contact.

- Pay special attention to fans: Dust accumulates heavily on fan blades and motor hubs:

- Hold fan blades stationary while vacuuming to prevent over-spinning

- Clean both intake and exhaust sides of fan assemblies

- Use brush attachments to loosen dust from blade surfaces

- Address dust filters: Many cases have internal dust filters that require regular cleaning.

Internal cleaning typically takes 20-40 minutes depending on the system’s complexity and dust accumulation level.

Motherboard and Sensitive Area Techniques

The motherboard contains the most sensitive components and requires extra caution:

- Use lowest effective suction setting: Reduce power to minimum when working near the motherboard.

- Employ the “hover technique”: Hold the vacuum nozzle slightly above the surface, allowing it to pull dust upward without direct contact.

- Clean expansion slots carefully: For empty PCIe and RAM slots:

- Use compressed air at a 45° angle to blow dust toward vacuum nozzle

- Never insert vacuum attachments into slots

- Use specialized electronics cleaning brushes for persistent dust

- Address the CPU area:

- Clean the heatsink fins with gentle vacuum pressure

- For heavy dust buildup, consider removing the CPU heatsink (requires thermal paste replacement)

- Clean fan blades individually while preventing rotation

- Handle capacitors with care: The tall cylindrical components on motherboards are particularly fragile:

- Maintain at least 1-inch clearance with vacuum nozzles

- Use soft brush attachments if cleaning is necessary

- Never apply direct pressure

- Clean RAM modules: If RAM removal is required:

- Document slot locations before removal

- Handle modules only by the edges

- Clean contacts with isopropyl alcohol on a lint-free cloth

- Vacuum slots gently before reinsertion

The motherboard cleaning process is the most delicate and typically takes 15-30 minutes to complete properly.

Post-Cleaning Verification

After cleaning, verify your work before powering up:

- Visual inspection: Using a flashlight, examine all components for:

- Remaining dust accumulation

- Loose or disconnected cables

- Components that may have been dislodged

- Foreign objects accidentally left inside

- Verify fan operation manually: Gently spin each fan with your finger to ensure free movement without unusual resistance or sounds.

- Check all connections: Confirm that all power and data cables are properly seated, especially if you’ve moved components during cleaning.

- Secure all components: Verify that expansion cards, RAM modules, and any other components are fully seated and secured.

- Replace case covers: Reassemble the computer case, ensuring all screws and clips are properly fastened.

- Power-up test: Reconnect peripherals and power, then boot the system while monitoring:

- Fan noise levels (should be lower after cleaning)

- Boot time (often improved with better cooling)

- Operating temperatures (use monitoring software to compare pre and post-cleaning)

- Document results: Record the cleaning date, process used, and temperature improvements for future reference.

This verification process takes 10-15 minutes but can prevent costly problems and confirm the effectiveness of your cleaning efforts.

Keyboard and Peripheral Cleaning Techniques

Keyboards and peripherals collect more direct contamination from human contact and require specialized cleaning approaches.

Removing Debris from Mechanical Keyboards

Mechanical keyboards with individual switches require specific cleaning techniques:

- Preparation:

- Disconnect the keyboard completely

- Take a “before” photo to document key layout

- Move to a clean workspace with good lighting

- Initial vacuum cleaning:

- Use a brush attachment on low power

- Clean between keys in a grid pattern, moving horizontally then vertically

- Pay special attention to areas showing visible debris

- Keycap removal (if necessary):

- Use a keycap puller tool (avoid improvised tools that may damage switches)

- Remove keycaps in small batches, cleaning as you go

- For heavily soiled keyboards, consider removing all keycaps

- Switch cleaning:

- With keycaps removed, vacuum the exposed switch tops using precision attachments

- Maintain 1/2-inch distance from switches to prevent damage

- Use compressed air at a 45° angle to dislodge particles toward vacuum nozzle

- Keycap cleaning:

- For light soiling: wipe with microfiber cloth dampened with isopropyl alcohol

- For heavy soiling: wash keycaps in warm water with mild soap, rinse thoroughly and dry completely before reinstallation

- Vacuum dry keycaps to remove any lint before reinstallation

- Reassembly:

- Refer to your documentation photo for correct key placement

- Press keycaps straight down onto switches until they snap into place

- Test each key after reinstallation

This process takes 30-60 minutes depending on cleaning depth but can dramatically extend keyboard lifespan and improve typing experience.

Membrane Keyboard Cleaning Approaches

Membrane keyboards (including laptop keyboards) require a gentler approach:

- Surface cleaning:

- Disconnect or power off the keyboard

- Use a vacuum with brush attachment on lowest setting

- Work in methodical rows, lifting debris from between keys

- Hold the vacuum 1/2 inch above the surface to prevent key cap removal

- Edge cleaning:

- Tilt the keyboard at different angles while vacuuming to access debris under the edges of keys

- Use crevice tools to reach difficult areas between key rows

- Stubborn debris removal:

- With the keyboard powered off and disconnected, gently press each key while vacuuming

- Use compressed air at a shallow angle to dislodge particles

- For laptops, consult manufacturer guidelines before using compressed air

- Surface sanitizing:

- Lightly dampen (not wet) a microfiber cloth with isopropyl alcohol

- Wipe key surfaces and spaces between keys

- Allow to dry completely before reconnecting

Membrane keyboard cleaning typically takes 10-20 minutes and should be performed monthly for heavily used keyboards.

Mouse and External Peripheral Cleaning

Mice and other peripherals collect oils and debris that affect performance:

- Optical/laser mice:

- Disconnect the mouse completely

- Vacuum the sensor area with precision attachment

- Clean mouse feet with a dry cotton swab

- Wipe body with slightly dampened microfiber cloth

- Pay special attention to textured areas where hand oils accumulate

- Mouse with scroll wheel:

- Vacuum around the scroll wheel from multiple angles

- Use a toothpick to gently separate visible debris, then vacuum it away

- Apply compressed air at low pressure if vacuum alone is insufficient

- Controller and gamepad cleaning:

- Vacuum seams and button edges using precision attachments

- Clean joystick bases where dust enters the mechanism

- Address textured grips using soft brush attachments

- External hard drives and peripherals:

- Focus on ventilation areas and connection ports

- Maintain 1-inch distance from any exposed circuitry

- Clean cooling vents at 45° angle to prevent pushing dust inside

- Docking stations and port replicators:

- Pay special attention to connection ports and cooling vents

- Use precision vacuum attachments for electrical contacts

- Clean docking connectors with compressed air, never vacuum directly

These peripherals typically require 5-10 minutes each for thorough cleaning.

Connection Port and Jack Cleaning Methods

Ports and connectors require extra precision:

- USB and standard ports:

- Use precision vacuum nozzles held 1/4 inch away from port openings

- Apply gentle suction without direct contact

- For stubborn debris, use wooden toothpicks (never metal) to carefully loosen debris while vacuuming

- Audio jacks:

- Use the smallest precision vacuum attachment

- Hold near the opening without insertion

- If debris is visible inside, use compressed air at very low pressure directed outward

- Card readers:

- Use crevice tool to clean the outer slot

- Never insert vacuum attachments into the reader mechanism

- Hold at 45° angle to pull debris outward

- Power ports:

- Ensure device is completely unplugged

- Use vacuum with brush attachment to clean around port edges

- Never insert conductive cleaning tools into power connections

Port cleaning typically takes 10-15 minutes for all connections on a device.

Special Considerations for Gaming Equipment

Gaming equipment presents unique challenges due to intensive use and complex designs:

- Gaming keyboards:

- Address backlight areas where dust is highly visible

- Clean macro keys and specialized buttons individually

- Pay extra attention to WASD keys and others with heaviest use

- Gaming mice:

- Clean sensor area with special attention to prevent performance issues

- Address button switches and scroll wheel with precision tools

- Clean weight adjustment compartments if present

- VR controllers and headsets:

- Focus on ventilation areas and face cushions

- Clean sensors with extreme care using lowest suction

- Address head straps and adjustment mechanisms where sweat and oils accumulate

- Racing wheels and specialty controllers:

- Clean calibration mechanisms and force-feedback components

- Address pedal assemblies where floor dust accumulates

- Clean cable strain relief areas where flexibility is essential

Gaming equipment often contains precision sensors and should be cleaned with extra care, typically requiring 15-20 minutes per device for proper maintenance.

Laptop-Specific Vacuum Cleaning Methods

Laptops present unique cleaning challenges due to their compact design and integrated components.

Accessing Ventilation Areas Safely

Laptops have intentionally restricted airflow pathways that require specialized cleaning approaches:

- Identify airflow patterns:

- Locate intake vents (typically on the bottom or sides)

- Find exhaust vents (usually on the sides or rear edge)

- Understand the intended airflow direction (generally bottom-to-side or bottom-to-rear)

- Prepare the laptop:

- Shut down completely (not sleep or hibernate)

- Disconnect all peripherals and power

- Remove the battery if user-removable

- Position on a clean, flat, non-static surface

- Clean external vents:

- Use crevice attachments with the vacuum on lowest setting

- Hold 1/2 inch away from the vent openings

- Work in a grid pattern, cleaning each vent section methodically

- Pay attention to the fan exhaust area where dust accumulation is typically highest

- Address cooling fins:

- Use angled crevice tools to reach cooling fins visible through vents

- Maintain distance to prevent fin damage

- Vacuum from multiple angles to capture dust from different approaches

- Fan cleaning considerations:

- Hold laptop fans stationary while vacuuming nearby

- Look for dust “ropes” that form at fan edges and remove carefully

- Never force air or vacuum pressure against fan rotation direction

This external cleaning process takes 10-15 minutes and should be performed every 1-3 months depending on environment.

Keyboard and Touchpad Cleaning

Laptop input devices collect significant debris and require specific approaches:

- Keyboard vacuum technique:

- Use brush attachment on lowest setting

- Hold at 1/2-inch distance from keytops

- Work row by row in a methodical pattern

- Tilt laptop at different angles to allow gravity to help dislodge particles

- Key edge cleaning:

- Use crevice tool held at 45° angle

- Work around each key’s perimeter without applying downward pressure

- Pay special attention to larger keys (spacebar, enter, shift) where more debris accumulates

- Touchpad area:

- Use brush attachment on lowest setting

- Clean from top to bottom, following normal finger movement patterns

- Address seams around touchpad perimeter where debris collects

- Clean touchpad buttons with special attention to travel areas

- Palm rest cleaning:

- Vacuum with brush attachment to remove loose particles

- Follow with microfiber cloth slightly dampened with isopropyl alcohol

- Pay special attention to textured surfaces where oils accumulate

This process typically takes 10-15 minutes and significantly improves both aesthetics and functionality.

Screen and Hinge Cleaning Considerations

Laptop screens and hinges require special attention:

- Screen cleaning preparation:

- Never vacuum directly on screen surfaces

- Use vacuum with brush attachment only on screen edges and bezels

- Hold vacuum at least 1 inch from screen surface

- Hinge cleaning:

- Vacuum dust accumulated in hinge mechanisms

- Position laptop at various angles to access different portions of the hinge

- Use precision attachments to reach recessed areas

- Address rubber stops and cushions where dust adheres

- Screen bezel cleaning:

- Use brush attachment on lowest setting

- Clean the perimeter in one direction (typically clockwise)

- Pay special attention to webcam and microphone areas

- Address corners where dust accumulation is typically highest

- Connection between screen and base:

- Clean the transition area between screen and base

- Address rubber cushions and contact points

- Use precision tools for ribbon cable areas (if visible)

Proper screen and hinge cleaning takes 5-10 minutes and prevents dust from affecting display quality or hinge durability.

Battery Area Precautions

The battery area requires specific safety considerations:

- For removable batteries:

- Remove battery following manufacturer guidelines

- Vacuum battery compartment with precision attachment

- Clean battery contacts with compressed air only, never vacuum directly

- Check for signs of corrosion or residue that may require professional attention

- For non-removable batteries:

- Focus on keeping ventilation paths around battery area clear

- Avoid applying pressure to the battery area

- Clean only visible exterior surfaces

- Be alert for unusual bulging or heat that may indicate battery issues

- Battery cooling pathways:

- Many modern laptops have specific cooling channels for battery temperature management

- Identify and clean these pathways with precision attachments

- Pay attention to thermal pads and heat distribution areas

- Safety considerations:

- Never use liquid cleaners around battery areas

- Avoid metal tools that could cause shorts

- If you notice unusual battery behavior after cleaning, discontinue use and seek professional service

Battery area cleaning typically takes 5-10 minutes and should be approached with caution.

Working Around Sealed Components

Modern laptops increasingly use sealed designs that present special challenges:

- Identify accessible areas:

- Determine which components can be safely cleaned without disassembly

- Focus on external vents and openings designed for airflow

- Understand which areas are intentionally sealed by manufacturers

- Sealed keyboard considerations:

- Many modern laptops have sealed keyboard decks

- Use only gentle vacuum pressure around keycaps

- Consider keyboard covers for prevention rather than intensive cleaning

- Bottom panel cleaning:

- Clean screws and panel seams before attempting any disassembly

- Use vacuum and brush on visible intake grilles

- Pay attention to rubber feet where dust accumulates

- When to seek professional help:

- Unusual overheating despite external cleaning

- Visible dust behind screens or inside sealed areas

- Fan noise that persists after external cleaning

- Performance issues suggesting internal thermal problems

For sealed devices, external cleaning typically takes 15-20 minutes and should be performed more frequently (every 4-6 weeks) since internal access is limited.

Server and Data Center Equipment Cleaning

Enterprise equipment in data centers requires specialized approaches due to density, uptime requirements, and environmental controls.

High-Density Environment Considerations

Data centers present unique cleaning challenges:

- Airflow management:

- Data centers use carefully designed hot/cold aisle configurations

- Cleaning should preserve rather than disrupt these airflow patterns

- Address both equipment and under-floor or overhead plenum spaces

- Contaminant types:

- Data centers face different contaminants than home environments:

- Zinc whiskers from floor tiles

- Concrete dust from building materials

- Fibers from cardboard packaging

- Metal particles from equipment installation

- Data centers face different contaminants than home environments:

- Static concerns:

- Lower humidity in data centers increases static risks

- Use only properly grounded ESD-safe equipment

- Verify grounding before each cleaning session

- Consider supplemental humidification during cleaning

- Scheduling considerations:

- Plan cleaning during maintenance windows

- Coordinate with cooling system maintenance

- Document all cleaning activities for compliance

- Consider staggered cleaning to maintain redundancy

These environmental considerations should inform your entire data center cleaning approach.

Rack-Mounted Equipment Techniques

Cleaning servers and rack equipment requires specialized procedures:

- External cleaning (equipment running):

- Use ESD-safe vacuums with HEPA filtration

- Clean front bezels and air intakes first

- Address cable management arms and structured cabling

- Document before/after temperatures to verify effectiveness

- Internal cleaning (equipment powered down):

- Follow proper shutdown procedures

- Clean from front to back following airflow patterns

- Remove dust filters for separate cleaning

- Pay special attention to:

- CPU heatsinks and memory sinks

- PCIe card edges and expansion slots

- Power supply intakes

- System board areas with passive cooling

- Rail and mounting hardware:

- Clean sliding rails and mechanisms

- Address mounting brackets and cage nuts

- Clean cable management accessories

- Vacuum rack vertical mounting rails

- Hot-swap component considerations:

- Clean around hot-swap drive bays

- Address fan modules and power supplies

- Clean blank filler panels

- Verify proper seating after cleaning

Rack equipment cleaning typically takes 20-30 minutes per server and should be performed quarterly or based on environmental monitoring.

Network Equipment Cleaning Methods

Network gear has specific cleaning requirements:

- Switch and router considerations:

- Focus on side-to-side airflow patterns

- Clean around port openings without contact

- Address LED indicators carefully

- Pay special attention to stacking ports

- Interface cleaning:

- Use specialized fiber optic vacuum tools for optical ports

- Clean copper port exteriors with precision tools

- Address management ports and console connections

- Clean LCD screens and status displays

- Redundant power systems:

- Clean power entry modules

- Address redundant fan systems

- Clean power cable strain reliefs

- Verify indicator operation after cleaning

- Module cleaning:

- Address removable line cards

- Clean chassis slots during module removal

- Verify proper seating after cleaning

- Document module locations when multiple components are removed

Network equipment typically requires 10-15 minutes per device and should be cleaned on the same schedule as server equipment.

Scheduled Maintenance Approaches

Consistent scheduling improves cleaning effectiveness:

- Tiered cleaning schedules:

- Weekly: External visual inspection

- Monthly: External vacuum cleaning

- Quarterly: Partial internal cleaning

- Semi-annually: Comprehensive internal cleaning

- Environmental monitoring:

- Use particle counters to verify air quality

- Monitor temperature deltas to identify clogged components

- Track humidity levels that affect static generation

- Consider airflow analysis to identify blockages

- Documentation systems:

- Record cleaning activities by equipment

- Track temperature changes after cleaning

- Maintain photographic records of before/after

- Note any anomalies for follow-up

- Staff training considerations:

- Ensure proper ESD procedures

- Develop equipment-specific cleaning protocols

- Maintain certification on specialized equipment

- Implement quality control verification

Proper maintenance scheduling reduces emergency cleaning needs and extends equipment life.

Professional vs. In-House Cleaning Comparison

Organizations face make-or-buy decisions regarding cleaning:

- Professional service advantages:

- Specialized equipment and expertise

- Insurance coverage for damaged components

- Consistent documentation and reporting

- No capital investment in cleaning equipment

- Typical cost: $20-50 per server, $500-2000 per rack

- In-house advantages:

- On-demand availability

- Staff knowledge of critical systems

- Integration with existing maintenance

- Lower per-cleaning costs over time

- Initial investment: $2000-5000 for quality equipment

- Hybrid approaches:

- In-house staff performs routine external cleaning

- Professionals handle semi-annual deep cleaning

- Split responsibilities based on equipment criticality

- Use professionals for initial cleaning and staff training

The best approach depends on facility size, equipment criticality, and available resources.

Maintenance Schedule and Best Practices

Establishing a consistent maintenance routine maximizes equipment longevity and performance.

Frequency Recommendations by Environment

Cleaning frequency should be tailored to your specific environment:

| Environment | External Cleaning | Internal Cleaning | Complete Overhaul |

|---|---|---|---|

| Home Office (Clean) | 3-4 months | 6-12 months | 24-36 months |

| Home Office (Dusty/Pets) | 1-2 months | 3-6 months | 12-24 months |

| Business Office | 2-3 months | 6 months | 18-24 months |

| Industrial Setting | 2-4 weeks | 2-3 months | 12 months |

| Data Center (Tier 1-2) | 1-2 months | 4-6 months | 12-18 months |

| Data Center (Tier 3-4) | Monthly | 3 months | 12 months |

| Educational Lab | Monthly | 3-4 months | 12 months |

| Medical Environment | 2-4 weeks | 2-3 months | 6-12 months |

Adjust these recommendations based on:

- Visual inspection results

- Performance metrics

- Temperature monitoring

- Environmental particle counts

Preventative Measures to Reduce Dust Buildup

Reducing dust entry is more effective than frequent cleaning:

- Environmental controls:

- Use room air purifiers with HEPA filtration

- Maintain 40-60% humidity to reduce static-attracted dust

- Consider positive pressure ventilation in dedicated computer rooms

- Implement regular room cleaning schedules

- Equipment placement:

- Elevate equipment off floors (minimum 6 inches)

- Maintain clearance from walls and obstructions

- Position intake vents away from high-dust areas

- Avoid placement near windows, doors, or HVAC vents

- Filtration systems:

- Install high-quality dust filters on computer cases

- Consider washable, reusable filter media

- Implement multi-stage filtration with coarse and fine elements

- Verify filter installation doesn’t restrict airflow excessively

- Cable management:

- Use proper cable management to reduce dust collection surfaces

- Elevate cables off floors when possible

- Bundle cables to reduce surface area

- Clean cable bundles during regular maintenance

- Peripheral considerations:

- Use keyboard covers when not in use

- Consider dust covers for equipment during extended downtime

- Position printers and paper-handling equipment away from computers

- Clean surrounding furniture regularly

These preventative measures can reduce cleaning frequency by 30-50% while improving equipment reliability.

Documentation and Tracking Systems

Systematic tracking improves maintenance effectiveness:

- Equipment inventory:

- Create detailed inventory with cleaning requirements

- Assign risk levels based on criticality and environment

- Track warranty and service information

- Note any special cleaning considerations

- Cleaning logs:

- Record date, technician, and procedures performed

- Document unusual findings or areas of concern

- Track consumables used (filters, cleaning supplies)

- Note temperature and performance improvements

- Photographic documentation:

- Capture before/after images of components

- Document progressive buildup between cleanings

- Photograph any damage or anomalies

- Use consistent perspectives for comparison

- Performance metrics:

- Track temperature changes after cleaning

- Monitor fan speeds and noise levels

- Record system performance benchmarks

- Note any reliability improvements

Proper documentation allows for data-driven adjustments to cleaning frequency and methods.

Combining Vacuum with Other Cleaning Methods

Vacuum cleaning works best as part of an integrated approach:

- Sequential cleaning process:

- Begin with vacuuming to remove loose debris

- Follow with compressed air for stubborn dust

- Use isopropyl alcohol for contact cleaning

- Apply appropriate lubricants after cleaning

- Compressed air integration:

- Use compressed air to dislodge dust toward vacuum nozzle

- Maintain lower pressure (30 PSI or less) to prevent component damage

- Hold cans upright to prevent liquid propellant discharge

- Consider electric air dusters for frequent use

- Contact cleaning methods:

- Use 91%+ isopropyl alcohol for electrical contacts

- Apply cleaning solutions to cloths, never directly to components

- Allow complete drying before powering equipment

- Consider specialized electronic contact cleaners for heavy contamination

- Application-specific techniques:

- Use soft brushes to loosen dust before vacuuming

- Apply specialized keyboard cleaners for heavy contamination

- Consider ultrasonic cleaning for removable, non-electronic components

- Use lint-free wipes for screen and optical surfaces

This integrated approach provides more thorough cleaning than any single method alone.

Warning Signs that Cleaning is Needed

Don’t wait for performance problems—watch for these early indicators:

- Audible indicators:

- Increased fan noise or pitch changes

- Clicking or scraping sounds from fans

- Unusual vibrations during operation

- Fans running constantly at high speed

- Thermal indicators:

- Rising idle temperatures

- Faster temperature increases under load

- Uneven temperature distribution

- Thermal throttling during normal operation

- Performance indicators:

- Extended boot times

- Laggy response during routine tasks

- Application crashes related to heating

- Unexpected shutdowns

- Visual indicators:

- Visible dust on intake grilles

- Dust trails around exhaust vents

- Accumulation on external components

- Discoloration from heat exposure

- Environmental indicators:

- Recent construction or renovation

- Seasonal changes affecting dust levels

- New pets or increased shedding

- Changes in room use or occupancy

Responding to these early warnings prevents performance degradation and component damage.

Troubleshooting Common Issues

Even with proper techniques, cleaning sometimes presents challenges.

Addressing Static Discharge Incidents

If static discharge occurs during cleaning:

- Immediate response:

- Stop cleaning immediately

- Disconnect power completely

- Allow equipment to sit untouched for 10-15 minutes

- Verify grounding equipment is functioning properly

- Assessment process:

- Inspect the area where discharge occurred

- Look for visible damage to components

- Check for burnt odors indicating component failure

- Document the incident with photos if possible

- Testing procedure:

- Reconnect power without peripherals

- Observe POST process and startup

- Run diagnostic software if available

- Test all functions systematically

- Remediation options:

- For minor issues, continue monitoring for 24-48 hours

- For significant problems, consult repair services

- Consider component replacement if damage is isolated

- Document for warranty or insurance purposes

Most static incidents cause either immediate catastrophic failure or no damage at all, but monitoring is essential to identify latent issues.

Dealing with Liquid Spills Alongside Dust

When liquid contamination complicates cleaning:

- Emergency response:

- Power off immediately (battery too if possible)

- Disconnect from power sources

- Position to allow drainage away from components

- Blot (don’t wipe) excess liquid with absorbent materials

- Cleaning approach:

- Allow 24-48 hours drying time before vacuum cleaning

- Use vacuum first to remove crystallized residue

- Focus on areas where liquid pooled

- Use isopropyl alcohol for final cleaning after complete drying

- Special considerations:

- Sugary drinks leave conductive residue requiring thorough cleaning

- Coffee and tea contain acids that can cause corrosion

- Carbonated beverages may leave residue in seams and connections

- Water with high mineral content leaves conductive traces

- Professional options:

- Consider ultrasonic cleaning for removable components

- Use specialized electronic cleaning solutions for severe contamination

- Consult repair services for valuable equipment

- Consider component-level cleaning when economical

Addressing liquid spills promptly minimizes long-term damage and simplifies subsequent cleaning.

Recovering from Cleaning-Related Damage

If cleaning causes component issues:

- Identify the problem:

- Note when the issue began relative to cleaning

- Document specific symptoms

- Determine if problem is intermittent or constant

- Isolate affected components

- Common cleaning damages:

- Dislodged cables or components

- Fan damage from excessive speed during cleaning

- Liquid intrusion from cleaning products

- Static damage to sensitive components

- Bent fins on heatsinks

- Resolution approaches:

- Reseat all cables and components

- Replace damaged cooling components

- Allow complete drying of any moisture

- Substitute known-good components to isolate issues

- Check for foreign objects introduced during cleaning

- Prevention strategies:

- Document component positions before cleaning

- Use appropriate tools for the task

- Follow manufacturer guidelines

- Practice techniques on less critical equipment

Most cleaning-related damage is preventable with proper technique and equipment.

When to Seek Professional Assistance

Recognize when DIY cleaning reaches its limits:

- Technical indicators:

- Persistent overheating despite cleaning

- Unusual noise continuing after cleaning

- Error codes or boot failures

- Components requiring specialized tools

- Equipment considerations:

- High-value equipment with warranty implications

- Mission-critical systems with redundancy requirements

- Legacy equipment with irreplaceable components

- Equipment with specialized cooling systems

- Environmental factors:

- Contamination beyond standard dust (chemical, liquid, smoke)

- Biological contamination requiring sanitization

- Equipment subjected to flood or fire damage

- Extremely dense dust buildup requiring ultrasonic cleaning

- Professional service options:

- Manufacturer warranty service

- Third-party repair centers

- On-site technical cleaning services

- Specialized electronics restoration companies

Professional services typically cost $75-150 per hour but offer expertise and appropriate equipment for challenging situations.

Identifying Cleaning-Resistant Issues

Some issues mimic dust-related problems but require different solutions:

- Hardware failures vs. dust symptoms:

- Dust issues typically develop gradually

- Hardware failures often occur suddenly

- Dust problems typically improve immediately after cleaning

- Component failures persist regardless of cleaning

- Common misdiagnosed issues:

- Thermal paste degradation (not dust)

- Fan bearing failure (not dust obstruction)

- Power supply voltage instability (not cooling issues)

- Software or driver conflicts (not hardware problems)

- Diagnostic approaches:

- Test with known-good components

- Monitor temperatures before and after cleaning

- Use software diagnostics for component testing

- Isolate variables through systematic testing

- Resolution pathways:

- Reapply thermal compounds

- Replace failing fans regardless of dust status

- Update firmware and drivers

- Consider component-level repairs for valuable equipment

Proper diagnosis prevents unnecessary cleaning and focuses efforts on actual issues.

Conclusion

Proper vacuum cleaning of electronics represents an investment in equipment longevity, performance, and reliability. By understanding the risks, using appropriate tools, and following systematic procedures, you can safely remove performance-robbing dust and debris from even the most sensitive electronic equipment.

The key principles of safe electronic vacuum cleaning include:

- Using ESD-safe equipment designed specifically for electronics

- Maintaining appropriate distance from sensitive components

- Working systematically from exterior to interior

- Combining vacuum techniques with complementary cleaning methods

- Establishing regular maintenance schedules based on environment

For home users, these practices can extend equipment life by 30-50% while maintaining peak performance. For businesses, proper cleaning reduces downtime, extends refresh cycles, and protects critical assets.

The most important takeaway is that prevention is more effective than remediation. Implementing dust-reduction strategies, proper equipment placement, and regular light cleaning prevents the need for extensive deep cleaning and minimizes the risk of dust-related failures.

Whether you’re cleaning a personal laptop, maintaining a gaming PC, or managing a data center full of servers, these principles and techniques provide a foundation for effective, safe electronics cleaning that preserves your investment and ensures reliable operation.