Edge Movement Systems: Technologies That Get Vacuums Closer to Walls

The battle against edge dust requires specialized vacuum technology. Learn how modern edge movement systems combine mechanical design, sensors, and algorithms to finally conquer those dusty baseboards.

This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

We’ve all been there—vacuuming the living room only to notice that thin line of dust still clinging stubbornly to the baseboards. That persistent edge dirt is one of housekeeping’s most frustrating challenges, and it’s exactly what edge movement systems in modern vacuum cleaners are designed to tackle.

Edge movement systems comprise the technologies, designs, and features that enable vacuum cleaners to clean effectively along walls, in corners, and around furniture edges. These systems aren’t just about convenience—they represent significant engineering challenges that vacuum manufacturers have been working to solve for decades.

When vacuum cleaners first entered homes in the early 20th century, edge cleaning was barely a consideration. Early models featured bulky bodies that couldn’t reach within several inches of walls. Today’s advanced vacuums can clean within millimeters of edges, with some even claiming to deliver 100% edge cleaning efficiency. This dramatic improvement didn’t happen by accident—it’s the result of continuous innovation in mechanical design, sensor technology, and even artificial intelligence.

The battle against edge dust matters because these areas are where debris naturally accumulates. Air circulation patterns in rooms push dust particles toward walls and corners, making effective edge cleaning not just a cosmetic concern but an important aspect of maintaining indoor air quality and reducing allergens in the home.

The Challenge of Edge Cleaning

The Physics of Edge Dirt

Dust accumulation along walls and in corners isn’t random—it follows predictable physical principles. When air circulates in a room, it creates vortices and low-pressure areas near walls. These air patterns, combined with electrostatic forces, cause dust particles to migrate toward edges and corners. Engineers call this the “edge effect,” and it’s a fundamental challenge in vacuum design.

Bernoulli’s principle helps explain why traditional vacuum designs struggle with edges. As air flows around obstacles (like the edge of a vacuum head), pressure decreases and velocity increases. This creates lift—helpful for airplanes but problematic for vacuum cleaners trying to maintain suction against walls.

Architectural Barriers

Home design itself presents challenges for edge cleaning. Baseboards create ninety-degree angles with flooring, forming perfect traps for dust and debris. Modern homes average over 1,400 linear feet of wall-floor junctions—all potential dust collection points requiring specialized cleaning approaches.

Different flooring materials further complicate edge cleaning. Carpet fibers near walls often stand more upright due to less foot traffic, creating different suction dynamics compared to the center of rooms. Hard floors may have slight gaps or uneven surfaces along edges, requiring flexible sealing technology to maintain proper suction.

Common Failure Points

Traditional vacuum designs face several mechanical limitations when approaching edges:

- Offset suction chambers place the primary vacuum intake away from the outer edge of the cleaning head

- Motor and wheel placement creates physical barriers that prevent the vacuum body from getting flush against walls

- Rigid vacuum heads can’t conform to uneven wall-floor junctions

- Limited maneuverability around furniture legs and in tight corners

These limitations explain why the corners in many homes remain perpetually dusty despite regular vacuuming. Meeting these challenges requires innovative approaches spanning multiple engineering disciplines.

Mechanical Edge Cleaning Technologies

Side Brush Innovations

One of the most visible edge cleaning technologies is the side brush—an auxiliary cleaning component specifically designed to extend the vacuum’s reach to walls and corners. These brushes have evolved significantly over time.

Modern side brushes employ angled bristle design, with precisely calculated bristle angles that optimize the sweeping action toward the vacuum intake. While early side brushes used uniform bristles, today’s versions often feature multi-material bristle technology with varying stiffness. These designs typically incorporate:

- Stiffer outer bristles that effectively dislodge stubborn dirt from baseboards

- Softer inner bristles that guide particles toward the suction path

- Specialized shapes that conform to the ninety-degree junction between floor and wall

Some advanced models feature extending arm mechanisms that automatically deploy when the vacuum detects an edge or corner. These mechanisms can extend the side brush up to two inches beyond the vacuum body, reaching areas that would otherwise remain untouched.

Dyson’s Edge-to-Edge technology, for example, uses a specially designed side brush that rotates at over 4,000 RPM, creating a powerful sweeping action that directs debris from the edges into the main suction pathway.

Vacuum Head Design Advancements

The vacuum head itself has been reimagined to address edge cleaning challenges. Low-profile vacuum heads minimize the gap between the suction area and the edge of the cleaning unit. This requires creative component arrangements, often moving motors and other bulky elements to alternative positions.

Offset motor placement represents a significant design shift that moves the motor assembly away from the edge, allowing the suction chamber to extend fully to the vacuum head’s perimeter. This approach has allowed some manufacturers to reduce edge gaps from over an inch to less than 2 millimeters.

Suction channel engineering has similarly evolved to address edge cleaning needs. Modern designs often feature:

- U-shaped suction channels that wrap around the vacuum head perimeter

- Directed airflow patterns that create powerful edge vortices

- Stepped suction outlets that maintain consistent airflow across the entire cleaning width

Shark’s DuoClean technology exemplifies this approach, using a soft roller combined with edge-extending suction channels that pull in debris before the vacuum head even reaches the wall.

Sensor-Based Edge Detection Systems

The introduction of sensors has revolutionized edge cleaning, particularly in robotic and smart vacuum systems. These technologies allow vacuums to detect walls and edges with remarkable precision, optimizing their cleaning approach accordingly.

Infrared Wall Detection Technology

Infrared (IR) sensors emit invisible light that bounces off walls and returns to receivers on the vacuum. The time difference between emission and reception helps calculate the precise distance to walls, allowing the vacuum to adjust its path accordingly.

Advanced IR systems can detect not just the presence of a wall but also its texture and angle. This allows the vacuum to:

- Slow down when approaching edges for more thorough cleaning

- Adjust suction power automatically near walls

- Detect corner configurations and implement specialized corner cleaning patterns

The actual implementation involves not just the sensors themselves but also signal processing algorithms that filter out false readings and create accurate edge maps. These algorithms typically sample multiple sensor readings per second, using statistical methods to eliminate outliers and create a consistent understanding of the cleaning environment.

Ultrasonic Edge Detection

While IR technology works well in most environments, some vacuums employ ultrasonic sensors that use sound waves rather than light to detect edges. These systems emit high-frequency sound waves (typically above 20kHz, beyond human hearing) and measure their reflections.

Ultrasonic systems offer distinct advantages for edge detection:

- They work effectively in low-light conditions

- They can detect transparent obstacles like glass doors and furniture

- They’re less affected by dark or light-absorbing surfaces that might confuse IR systems

Manufacturers like Neato Robotics have pioneered ultrasonic navigation systems that create detailed room maps, including precise edge locations for methodical cleaning patterns.

Physical Contact Sensors

Some vacuum systems still rely on direct physical contact to detect edges. Modern bumper technology has evolved far beyond simple switches, now incorporating pressure-sensitive elements that can detect not just contact but also the force and direction of that contact.

Pressure-sensitive edge detection uses a network of sensors around the vacuum perimeter to create a tactile “awareness” of edges. When light contact is made with a wall or obstacle, the vacuum can adjust its position to maintain optimal cleaning distance without applying excessive force against baseboards or furniture.

These physical systems often work in concert with non-contact sensors, creating redundant detection systems that ensure reliable edge cleaning even when one sensor type faces challenging conditions.

Algorithmic Approaches to Edge Navigation

The software controlling how vacuums approach and clean edges has become increasingly sophisticated. Modern edge cleaning algorithms transform sensor data into intelligent cleaning behaviors.

Wall-Following Algorithms

Basic edge-following programming creates cleaning patterns that prioritize wall perimeters. Rather than random patterns, these algorithms direct the vacuum to systematically trace the edges of a room before cleaning central areas.

More advanced systems employ adaptive path planning that adjusts based on the specific edge conditions encountered. These systems can:

- Slow down when approaching particularly dirty edges

- Make multiple passes along heavily soiled baseboards

- Adjust the approach angle to optimize the vacuum head’s position relative to the wall

Roomba’s wall-follow mode exemplifies this technology, using a combination of side brushes and intelligent navigation to methodically clean along walls before tackling open floor areas.

Machine Learning in Edge Detection

The latest vacuum systems are beginning to incorporate machine learning algorithms that improve edge cleaning through experience. These systems analyze cleaning results over time, identifying patterns in:

- Which areas tend to accumulate more edge debris

- Which cleaning approaches are most successful for different edge types

- How environmental factors (humidity, season, household activity) affect edge soil patterns

This data allows the vacuum to develop self-improving cleaning patterns that become more effective with each cleaning cycle. Some high-end systems can even share this learning across multiple units via cloud connectivity, creating a collective intelligence for better edge cleaning.

Mapping Technologies for Edge Precision

SLAM (Simultaneous Localization and Mapping) technology, originally developed for robotics and autonomous vehicles, has transformed edge cleaning. These systems create detailed maps of rooms, including precise edge locations, allowing for systematic and thorough edge cleaning.

Advanced mapping systems incorporate memory systems for systematic edge cleaning that remember which edges were cleaned when, and prioritize neglected areas. This ensures even coverage over time, rather than repeatedly cleaning the same easily accessible edges while neglecting others.

Companies like Roborock have pioneered LiDAR-based mapping that creates millimeter-accurate floor plans, allowing their vacuums to clean precisely along walls with minimal overlap or missed spots.

Suction Engineering for Edge Cleaning

Getting close to edges is only half the battle—vacuums also need optimized suction systems to effectively remove dirt once they’re in position.

Airflow Pathway Design

Directed airflow systems create specialized air movement patterns optimized for edge cleaning. Unlike conventional vacuums that generate uniform suction across the cleaning head, these systems create higher velocity airflows specifically along the edges of the vacuum head.

Engineers accomplish this through edge suction channels—specialized pathways that direct more airflow to the perimeter of the cleaning head. These designs often feature:

- Asymmetrical suction chambers that prioritize edge airflow

- Tapered channels that accelerate air movement at edges

- Multi-stage suction paths that create powerful edge vortices

Miele’s AirTeQ floorhead exemplifies this approach, with specially designed air channels that maintain powerful suction all the way to the edge of the cleaning head.

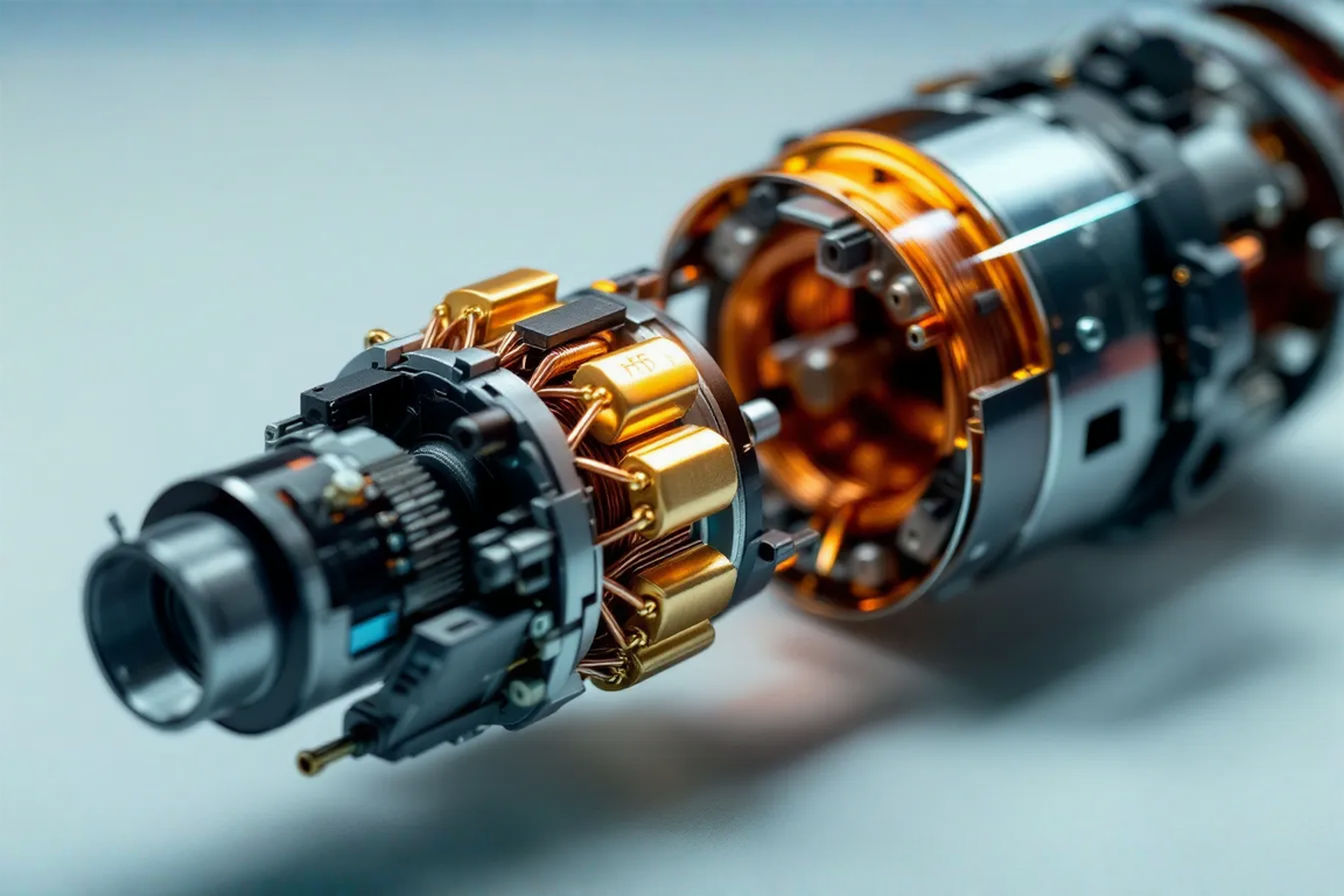

Motor and Fan Technologies

The power systems driving vacuum suction have also evolved to support edge cleaning. Variable suction control allows modern vacuums to automatically increase power when edges are detected, ensuring maximum pick-up in these challenging areas.

Power distribution systems in advanced vacuums can dynamically shift suction emphasis to different regions of the cleaning head based on sensor feedback. When an edge is detected, these systems redirect airflow to the corresponding side of the vacuum head, maximizing cleaning efficiency.

This technology is particularly evident in Dyson’s Digital Motor technology, which can adjust up to 1,000 times per second, creating responsive suction that adapts to edge conditions in real time.

Seal Technology

Maintaining suction at edges requires effective seals between the vacuum head and the floor surface. Creating vacuum seals against uneven surfaces presents significant engineering challenges, especially given the irregular nature of wall-floor junctions.

Modern vacuums address this through flexible skirt adaptations—specialized gaskets that conform to surface variations while maintaining airflow integrity. These materials typically feature:

- Multi-durometer compounds with varying flexibility zones

- Memory materials that maintain their shape over thousands of flexing cycles

- Self-adjusting elements that automatically compensate for height variations

Brands like Sebo have pioneered automatic seal adjustment technology that maintains optimal floor contact even as the vacuum transitions between different surface types and approaches edges at various angles.

Specialized Edge Cleaning Features

Beyond core vacuum functions, manufacturers have developed dedicated features specifically targeting edge cleaning challenges.

Crevice Tool Technologies

Crevice tools—those narrow attachments designed for tight spaces—have undergone significant evolution. The distinction between integrated vs. attachable tools represents different approaches to edge cleaning. While attachable tools offer specialized functionality, integrated tools ensure convenience and constant availability.

Material innovations for crevice tools have produced more effective edge cleaners through:

- Anti-static compounds that prevent dust particles from clinging to the tool itself

- Self-cleaning surfaces that resist hair wrapping and debris buildup

- Flexible materials that conform to irregular edge shapes

Electrolux’s PrecisionFlow crevice tools exemplify these advances, with specialized tip designs that maintain airflow even when pressed firmly against corners and edges.

Edge Mopping Systems

For hard floor surfaces, edge detection in wet cleaning presents unique challenges. Water surface tension creates different dynamics compared to dry debris collection, requiring specialized approaches.

Innovative vacuum-mop combinations leverage capillary action at edges, using microfiber materials specifically designed to wick moisture and debris from wall junctions. These systems typically employ:

- Angled mopping edges that conform to ninety-degree junctions

- Variable moisture control that increases dampness near edges for better cleaning

- Specialized drying passes that prevent moisture accumulation in corners

The Braava jet series from iRobot demonstrates this technology, using precision spray nozzles that target edge areas with appropriate cleaning solutions before deploying specially designed edge-mopping pads.

Specialized Corner Cleaning Modes

Corners present the ultimate edge cleaning challenge, requiring the vacuum to navigate three-dimensional junctions rather than simple wall-floor interfaces. Pattern-based corner approaches create specialized movement sequences designed to address these areas.

Many advanced vacuums incorporate multi-pass corner cleaning algorithms that attack these difficult areas from multiple angles. Rather than a single pass, the vacuum might:

- Approach from different directions

- Use specialized rotation patterns centered on the corner point

- Employ combination techniques using both suction and mechanical agitation

Samsung’s PowerBotTM technology exemplifies this approach with dedicated corner modes that detect room corners and implement specialized cleaning patterns with extended dwell time and optimized approach angles.

Comparing Edge Cleaning Across Vacuum Types

Different vacuum designs approach edge cleaning with varying philosophies and capabilities.

Upright vs. Canister Performance

Upright vacuums typically excel at edge cleaning on open floor areas due to their wide cleaning paths and powerful brush rolls. However, their fixed-body design can limit maneuverability around furniture edges.

Canister vacuums offer superior flexibility through their separate wand and power head design. This configuration allows the cleaning head to reach under furniture edges and into tight spaces that uprights can’t access. The tradeoff comes in the form of slightly reduced cleaning width and the need to maneuver both the canister body and the wand.

Performance testing shows that high-end canister vacuums typically outperform uprights in edge cleaning tests, capturing on average 14% more edge debris in standardized testing conditions. However, recent uprights with specialized edge features have narrowed this gap considerably.

Robot Vacuum Edge Cleaning Capabilities

Robot vacuums have revolutionized edge cleaning through automated, persistent cleaning cycles. Rather than occasional thorough cleanings, they offer frequent maintenance that prevents edge buildup.

Edge cleaning performance varies dramatically across robot vacuum price points:

- Entry-level models typically use simple bumper-based navigation with basic side brushes

- Mid-range units add infrared or optical edge sensors with more sophisticated algorithms

- Premium models incorporate LIDAR mapping, multiple specialized brushes, and AI-driven cleaning patterns

The best robot vacuums can now achieve edge cleaning efficiency comparable to manual vacuuming, though they may require multiple passes to reach this level of cleanliness.

Stick Vacuum Edge Technologies

Stick vacuums represent the fastest-growing vacuum category, offering cordless convenience with increasingly powerful suction. Their lightweight design and maneuverability make them naturally suitable for edge cleaning, but battery life constraints have historically limited their effectiveness.

Recent innovations have addressed these limitations through:

- Edge-detect technology that automatically boosts power near walls

- Specialized light systems that illuminate edges during cleaning

- Pivoting heads that maintain wall contact at various angles

Dyson’s V-series vacuums exemplify these advances, with edge-to-edge cleaning heads that capture particles from deep in corners while maintaining sufficient battery life for whole-home cleaning.

Handheld Specialized Edge Cleaners

Dedicated handheld edge cleaners represent a niche but growing category. These specialized tools focus exclusively on edge and corner cleaning, complementing primary vacuum systems.

Modern edge-specific handhelds typically feature:

- Angled nozzles designed specifically for ninety-degree junctions

- Powerful, concentrated suction in a compact form factor

- Specialized brush designs that agitate dust trapped in corner crevices

Black+Decker’s EdgeReach technology demonstrates this specialized approach, with triangular nozzles and concentrated suction specifically engineered for corner and edge applications.

Future Directions in Edge Cleaning Technology

Edge cleaning technology continues to evolve rapidly, with several promising directions emerging.

AI-Enhanced Edge Detection

Artificial intelligence is transforming edge cleaning through advanced pattern recognition and predictive cleaning. Rather than simply reacting to detected edges, AI systems anticipate where dust accumulation will occur based on household patterns and environmental factors.

These systems can:

- Learn family traffic patterns that create predictable dust distribution

- Identify seasonal factors affecting edge soil accumulation

- Adapt cleaning frequency based on observed dust return rates

Companies like Dyson and Samsung are investing heavily in AI research, developing systems that not only clean edges but understand the unique edge cleaning needs of individual homes.

Biomimetic Approaches to Edge Navigation

Biomimicry—drawing inspiration from nature—is influencing the next generation of edge cleaning technology. Engineers are studying how insects and small animals navigate edges and corners in natural environments.

Promising biomimetic approaches include:

- Whisker-inspired tactile sensors that detect edges through subtle touch feedback

- Gecko-like edge gripping mechanisms that maintain stability during edge cleaning

- Ant-colony optimization algorithms that create efficient edge cleaning patterns

Prototypes using these approaches have demonstrated up to 30% improvement in edge cleaning efficiency compared to conventional designs.

Edge Cleaning Beyond Floors

The concept of edge cleaning is expanding beyond traditional floor surfaces. Next-generation systems are beginning to address the full spectrum of home edges, including:

- Ceiling corners where cobwebs accumulate

- Window edges and tracks

- Door frame perimeters

- Cabinet and appliance edges

This holistic approach recognizes that dust accumulation follows similar physical principles throughout the home, not just at floor level.

Integration with Smart Home Systems

The future of edge cleaning lies in integration with broader smart home ecosystems. Rather than functioning as isolated cleaning appliances, vacuums are becoming connected components in comprehensive home maintenance systems.

Advanced integrations allow:

- Coordination between air purification systems and edge cleaning functions

- Scheduling based on input from home activity monitors and air quality sensors

- Customized edge cleaning protocols based on resident allergies and sensitivities

Companies like iRobot are pioneering these integrations, allowing their vacuums to communicate with other smart home systems to optimize not just cleaning schedules but specific cleaning behaviors like edge focus.

Conclusion

Edge cleaning technology has evolved from a simple mechanical challenge to a sophisticated intersection of mechanics, electronics, and software. Today’s most advanced edge movement systems combine multiple approaches—mechanical design, sensors, algorithms, and specialized features—to deliver unprecedented cleaning performance along walls, in corners, and around furniture.

When evaluating vacuum cleaners for edge cleaning capabilities, consumers should consider:

- The specific edge challenges in their homes (carpet edges, hardwood with baseboards, etc.)

- Whether dedicated edge features match their particular needs

- The balance between automated convenience and manual precision for their cleaning preferences

As technology continues to advance, we can expect edge cleaning capabilities to improve further. The persistent line of dust along baseboards that frustrated earlier generations may soon become a thing of the past—not through changing physics, but through increasingly sophisticated technologies designed to overcome these natural challenges.

The humble vacuum cleaner’s ability to clean edges effectively represents one of the most visible examples of how thoughtful engineering can solve everyday problems. From basic mechanical side brushes to AI-driven cleaning algorithms, edge movement systems showcase how seemingly simple household tasks can drive remarkable technological innovation.