Business-Grade Vacuum Maintenance at Home: Extending Life Through Commercial Methods

Discover how implementing commercial vacuum maintenance practices at home can extend your machine’s life from 5 years to 15+ while ensuring consistently powerful cleaning performance throughout.

This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

The average residential vacuum cleaner typically lasts 5-7 years before requiring replacement. However, properly maintained commercial-grade machines often serve businesses reliably for 15-20 years or more. This stark contrast reveals an important truth: the maintenance approach matters just as much as the machine itself.

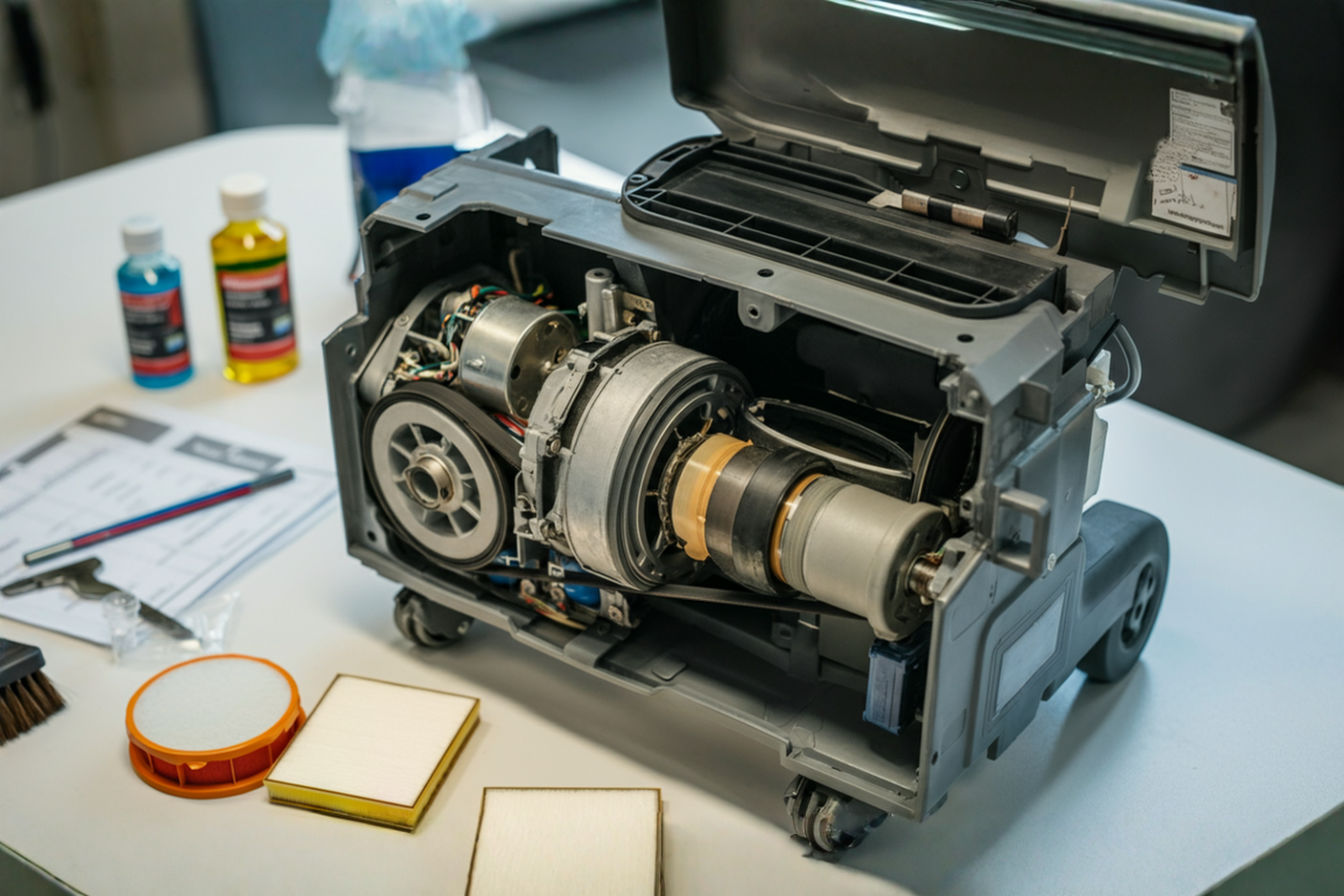

Business-grade vacuum cleaners represent significant investments designed for durability and consistent performance under heavy use. These robust cleaning tools differ substantially from their residential counterparts in construction, power systems, and maintenance requirements. When these commercial maintenance principles are applied to home use, even moderately priced vacuum cleaners can dramatically outlast their expected service life.

Adopting professional maintenance techniques offers numerous benefits beyond extended lifespan. These practices ensure consistent cleaning performance, reduce replacement costs, minimize repair frequency, and maintain peak energy efficiency throughout the machine’s life. With commercial vacuum cleaners increasingly finding their way into homes, understanding these specialized maintenance approaches becomes even more valuable.

This comprehensive guide explores how to implement commercial-grade maintenance routines in a home setting, transforming ordinary vacuum care into a systematic approach that mirrors professional standards. By following these guidelines, your vacuum cleaner can deliver exceptional performance year after year, ultimately saving money while providing superior cleaning results.

Understanding Business-Grade Vacuum Cleaners

Before delving into maintenance specifics, it’s essential to understand what truly distinguishes commercial vacuum cleaners from standard residential models. These differences directly inform the maintenance approaches required for optimal performance and longevity.

Commercial vacuum cleaners feature industrial-grade construction designed for daily, extended operation. This typically includes metal components where residential models use plastic, reinforced connection points, and heavier-duty casings designed to withstand impacts. The power systems represent another major difference, with commercial units employing larger, more efficient motors with advanced cooling systems that prevent overheating during prolonged use.

Filtration represents a critical point of differentiation. Business-grade machines incorporate multi-stage filtration systems with commercial-quality filters designed for vastly more operating hours before replacement becomes necessary. Many employ HEPA filtration systems certified for removing 99.97% of particles down to 0.3 microns, maintaining consistent air quality even in demanding environments.

Several distinct categories of commercial vacuums exist, each with unique maintenance considerations:

Upright commercial vacuums prioritize powerful brush agitation and wide cleaning paths, making them ideal for large carpeted areas. Backpack commercial units emphasize ergonomics and operator comfort during extended use, typically featuring specialized harness systems and lightweight construction. Canister models offer exceptional versatility through varied attachments while maintaining industrial-grade suction power. Wet/dry commercial vacuums handle diverse cleanup challenges with specialized filtration and collection systems designed for both liquid and dry debris.

Leading manufacturers in the commercial space include Hoover Commercial, ProTeam, Sanitaire, Oreck Commercial, and Nilfisk. These companies design their products specifically for commercial applications but increasingly offer consumer versions of their professional models.

The Economics of Commercial Vacuum Maintenance

The financial case for adopting commercial maintenance practices proves compelling when analyzed objectively. Commercial-grade vacuum cleaners typically cost between $300-$800, compared to $100-$300 for standard residential units. However, this initial price difference tells only part of the story.

A meticulously maintained commercial vacuum might serve effectively for 15-20 years, while even well-maintained residential models rarely exceed 7-10 years of useful service. This extended lifespan effectively reduces the annual cost of ownership by spreading the initial investment across more years of service.

Repair economics further favor commercial units. These machines are designed for modular repair, with standardized, readily available parts and straightforward access to components. Manufacturing standardization means replacement parts remain available for decades, whereas residential models often become functionally obsolete when parts are discontinued after just a few years.

Without proper maintenance, performance degradation follows a predictable pattern. Suction power typically drops 15-20% within the first year without maintenance, accelerating to 40-50% by year three. This decline directly impacts cleaning effectiveness while ironically requiring more time and electricity to achieve inferior results.

Consider this calculation: a $600 commercial vacuum lasting 15 years costs $40 annually, while a $200 residential unit lasting 5 years costs the same $40 annually—but with significantly less power and effectiveness in later years. Factor in the cost of professional cleaning services needed when vacuums perform poorly, and the economics clearly favor the commercial maintenance approach.

Daily and Weekly Maintenance Routines

The foundation of commercial vacuum longevity rests on consistent daily and weekly maintenance habits. These simple procedures prevent minor issues from developing into major problems and maintain optimal performance between deeper maintenance sessions.

After each use, perform a quick post-use inspection by examining the machine while it’s still warm. Check for unusual odors that might indicate motor stress or burning dust. Listen for any new or unusual sounds during shutdown that could signal developing mechanical issues. This proactive approach helps identify problems at their earliest, most treatable stage.

Proper emptying techniques vary by collection system type. For bagged systems, remove the bag when it reaches 2/3 capacity rather than waiting until completely full. This prevents motor strain and maintains optimal airflow. With bagless systems, empty collection chambers after each use and regularly clean the cyclonic filter components with compressed air. HEPA containment systems require special attention—always empty them in outdoor areas while wearing a mask to prevent reintroducing filtered particles into your home environment.

Quick-clean maintenance points should become part of your routine after every few uses. Clean the brush roll by removing hair and thread before they can bind the bearings or damage the belt. Inspect intake ports for blockages that might restrict airflow. Examine the entire length of the hose for developing cracks or internal blockages using a flashlight.

Proper storage significantly impacts longevity. Store your vacuum in a cool, dry location with the cord properly wrapped—never tightly wound around hooks, which damages internal wiring over time. Hang attachments rather than storing them in piles, preventing warping and damage to crucial sealing edges.

Weekly deep cleaning should include wiping down the entire exterior with a microfiber cloth, cleaning or replacing pre-motor filters according to manufacturer specifications, and inspecting wheels for debris that might impact mobility. Developing a simple maintenance tracking system—even a basic wall calendar—helps ensure no maintenance tasks are overlooked.

Monthly Maintenance Procedures

Monthly maintenance sessions focus on components subject to medium-term wear and contamination. This more thorough approach prevents performance degradation while addressing developing issues before they affect other systems.

Filter maintenance represents the most critical monthly task. Commercial vacuum cleaners typically employ multiple filtration stages, each requiring specific maintenance:

Primary filters typically capture larger particles and protect subsequent filtration stages. These should be inspected monthly and cleaned according to manufacturer specifications—usually by tapping out debris or gentle washing. Secondary filters capture medium-sized particles and often benefit from compressed air cleaning followed by gentle washing when appropriate. HEPA filters require careful maintenance, typically involving replacement rather than cleaning to maintain certification standards. Motor protection filters prevent fine dust from entering the motor housing and should never be operated when wet or damaged.

Belt inspection and replacement follows a specific protocol. Examine the belt for glazing (shiny appearance), cracks, stretching, or debris. Most commercial vacuums use flat belts rather than round ones, requiring proper tensioning during replacement. Keep manufacturer-recommended belts on hand, as using incorrect specifications significantly impacts performance and can damage the motor.

Brush roll maintenance involves removing the brush assembly monthly to clean the end bearings and inspect the bristles for wear patterns that might indicate alignment issues. Metal brush rolls found in many commercial units require different maintenance than plastic residential versions, often benefiting from bearing lubrication with specialized products.

The motor housing deserves monthly inspection for dust buildup on cooling fins and air intake screens. Dust-covered motors operate at higher temperatures, dramatically reducing service life. Use compressed air to clean these components, always blowing from the inside outward to prevent driving debris deeper into the motor.

Electrical system checks should include examination of the entire cord length for developing cracks or plug damage. Inspect internal wiring connections when accessible, looking for heat discoloration that might indicate developing resistance points.

Quarterly and Annual Maintenance

Seasonal maintenance addresses deeper systems and components that degrade more slowly but still require regular attention. These procedures often mirror manufacturer-recommended service intervals for commercial settings, adapted for home use frequency.

Quarterly deep cleaning of the motor cooling system prevents the leading cause of premature vacuum failure: heat damage. Remove access panels as directed in the user manual to expose the motor cooling channels. Use compressed air and specialized vacuum-safe electronic cleaning products to remove dust buildup from cooling fins and air passages. This procedure alone can extend motor life by years.

Bearing lubrication techniques vary by component. Most commercial vacuum bearings benefit from 3-4 drops of lightweight machine oil applied semiannually. Avoid household lubricants like WD-40, which can damage specialized commercial bearing materials. Proper lubrication prevents the distinctive high-pitched whine that precedes bearing failure.

Comprehensive suction testing provides objective performance tracking. Simply place a dollar bill under the vacuum head on hard flooring—a properly functioning machine should hold the bill firmly when on maximum suction. Documenting these results creates a performance baseline for tracking degradation over time.

Noise and vibration assessment helps identify developing mechanical issues before failure. Use a smartphone decibel meter app to establish baseline noise levels during normal operation. Significant increases in operating volume typically indicate developing problems requiring attention.

Annual professional inspection complements home maintenance for optimal results. Many vacuum repair shops offer comprehensive annual service packages that include disassembly, internal cleaning, component testing, and reassembly with proper lubrication. This professional intervention costs far less than eventual replacement and ensures all systems function properly.

Preventative parts replacement often proves more economical than emergency repair. Components like belts, filters, and brush rolls should be replaced according to manufacturer hours-of-use guidelines rather than waiting for failure. This approach prevents the cascade of damage that often occurs when one component fails during operation.

Troubleshooting Common Issues

Even with diligent maintenance, occasional issues arise requiring specific troubleshooting approaches. Understanding these common problems and their solutions empowers owners to resolve many issues without professional intervention.

Loss of suction represents the most frequently encountered problem. Diagnosis involves systematically isolating the cause by checking for bag/container fullness, filter clogs, hose blockages, and belt integrity. A methodical approach saves time by identifying the specific cause rather than replacing components unnecessarily. Remove the hose and check for suction at the machine body—if strong there but weak at the cleaning head, the obstruction lies between these points.

Unusual noises provide valuable diagnostic information. High-pitched whines typically indicate bearing issues. Rhythmic thumping suggests an unbalanced brush roll or foreign object. Grinding noises almost always signal serious mechanical problems requiring immediate shutdown to prevent further damage. Each sound correlates with specific components, enabling targeted inspection and repair.

Overheating problems commonly stem from airflow restrictions or overloaded dust collection systems. Commercial vacuums feature thermal protection that shuts down the motor before damage occurs. Address frequent thermal shutdowns immediately, as they indicate serious underlying issues that will eventually cause permanent failure.

Brush roll issues manifest through uneven cleaning performance. If carpet has zebra-like strips of uncleaned material, the brush roll may have bald spots or obstructions. Remove the brush assembly completely, clean thoroughly, and test rotation by hand to identify binding or resistance that signals developing problems.

Power and electrical concerns require careful attention to safety. Intermittent power typically indicates cord damage or switch failure. Never operate a vacuum with damaged electrical components—this represents both a fire and shock hazard. Modern commercial vacuums incorporate sophisticated circuit protection that may trigger from causes beyond the vacuum itself, such as home wiring issues.

When determining whether to attempt DIY repair versus seeking professional service, consider three factors: safety risk, tool requirements, and parts availability. Electrical system repairs nearly always warrant professional service, while filter replacement and basic maintenance can be safely performed at home with minimal tools.

Commercial-Grade Cleaning and Maintenance Products

Professional-grade maintenance products deliver superior results compared to general household cleaners. These specialized formulations address the unique materials and contaminants found in vacuum systems without damaging sensitive components.

Professional-grade cleaning solutions designed specifically for vacuum parts utilize non-residue formulations that remove embedded dirt without leaving films that attract new debris. These typically feature different pH values than household cleaners, making them safer for the specialized plastics used in commercial vacuum construction.

Specialized maintenance tools enhance effectiveness and prevent damage during service procedures. Consider investing in a vacuum-specific toolkit including cleaning brushes with non-scratch bristles, specialized belt removal tools, and bearing maintenance equipment. These purpose-built tools prevent the damage often caused when using improvised alternatives.

Commercial lubricants designed specifically for vacuum applications outperform general-purpose products. These specialized formulations remain stable at the high operating temperatures found in vacuum motors while resisting dust adhesion. Using inappropriate lubricants represents a common cause of premature failure, as household oils often break down under vacuum operating conditions.

Filter treatments and protectants extend filter life by maintaining porosity while enhancing particle capture. These products, widely used in commercial applications, create an electrostatic charge that improves filtration efficiency without restricting airflow. Apply these treatments after cleaning primary filters to maintain optimal performance.

Motor cleaning systems designed for commercial use safely remove carbon dust and debris accumulation from motor components without damaging insulation materials or electrical connections. These typically employ fast-evaporating solvents that leave no residue to interfere with electrical conductivity.

Professional maintenance supplies can be sourced through commercial cleaning supply distributors, specialized online retailers, and some vacuum service centers. Many manufacturers sell commercial-grade maintenance kits designed specifically for their machines, containing all necessary cleaning products and tools for comprehensive maintenance.

Creating a Maintenance Schedule and Tracking System

Systematic maintenance requires organization. Creating a structured maintenance schedule transforms sporadic care into a comprehensive system that ensures no critical procedures are overlooked.

Building a personalized maintenance calendar begins with reviewing the manufacturer’s recommended service intervals, then adapting them to your specific usage patterns. Commercial recommendations typically specify maintenance by hours of operation, while home users generally find calendar-based scheduling more practical.

Consider whether usage-based or time-based scheduling better suits your situation. Heavy users should follow usage-based maintenance timetables, performing key procedures after specified hours of operation. Occasional users may find time-based scheduling more appropriate, with maintenance performed at calendar intervals regardless of usage frequency.

Documentation and record-keeping provide valuable historical context for troubleshooting and repair decisions. Record all maintenance procedures, replacement parts, and performance observations in a dedicated maintenance log. This documentation proves particularly valuable when unusual issues arise, enabling pattern recognition that helps identify root causes.

Digital tools streamline maintenance tracking through automated reminders and comprehensive record-keeping. Many smartphone apps designed for general home maintenance can be customized for vacuum care schedules. These tools provide convenient access to maintenance history and automatically generate reminders for upcoming procedures.

Performance benchmarking creates objective measurements of how your vacuum functions over time. Simple tests like measuring airflow with an anemometer, tracking amperage draw with a power meter, or documenting cleaning effectiveness on standardized debris provide data-driven insights into developing issues before they become evident through poor performance.

Maintenance logging templates organize information consistently for easier analysis. Create a simple template including date, procedures performed, parts replaced, observations, and next scheduled maintenance date. This systematic approach ensures critical information remains available when needed for future service decisions.

Conclusion

Implementing commercial maintenance practices transforms vacuum care from reactive repair to proactive preservation. These systematic approaches directly address the most common causes of premature failure while maintaining consistent performance throughout the machine’s extended service life.

The long-term benefits extend beyond mere cost savings. Properly maintained vacuums clean more effectively, requiring fewer passes to achieve desired results. They operate more efficiently, consuming less electricity while delivering superior performance. They filter air more effectively, improving indoor air quality and reducing dust recirculation. Perhaps most importantly, they provide reliable service for years beyond their expected replacement date.

The most effective approach combines daily awareness, weekly attention to developing issues, monthly component maintenance, and annual professional servicing. This multi-layered strategy mirrors commercial maintenance protocols while remaining practical for home implementation.

As vacuum technology continues evolving, these fundamental maintenance principles remain remarkably consistent. The specific components may change, but the core practices of cleaning, inspection, lubrication, and preventative replacement transcend specific models or technologies.

Begin implementing these commercial maintenance practices today by establishing your baseline maintenance schedule, assembling appropriate tools and supplies, and documenting your vacuum’s current condition. This initial investment of time yields substantial returns through extended service life, improved performance, and significantly reduced lifetime ownership costs.

By applying these professional standards to home vacuum maintenance, you transform an ordinary appliance into a commercial-grade cleaning tool designed to deliver exceptional performance for decades rather than years.